Phakathi nenqubo yokubumba umjovo, kuvamile ukuhlangana neziphambeko ezihlukahlukene ezingxenyeni ezibunjiwe, ezingaba nomthelela kwikhwalithi nokusebenza kwemikhiqizo.Lesi sihloko sihlose ukuhlola ezinye zeziphambeko ezivamile ezingxenyeni ezibunjwe ngomjovo futhi sixoxe ngezindlela zokubhekana nalezi zinkinga.

1.Izimpawu zokugeleza:

Imigqa egelezayo yiziphambeko zezimonyo ezibonakala ngemigqa engenambala, imigqa, noma amaphethini abonakala ebusweni bengxenye ebunjiwe.Le migqa yenzeka lapho ipulasitiki encibilikisiwe ihamba ngesivinini esihlukile kulo lonke isikhunta somjovo, okuholela emazingeni ahlukene okuqiniswa kweresin.Imigqa egelezayo imvamisa iyinkomba yejubane lomjovo eliphansi kanye/noma ingcindezi.

Ukwengeza, imigqa yokugeleza ingavela lapho inhlaka ye-thermoplastic igeleza ezindaweni zesikhunta ezinobukhulu obuhlukahlukene bodonga.Ngakho-ke, ukugcina ukujiya kodonga okungaguquki nokuqinisekisa ubude obufanele bama-chamfer nama-fillet kubalulekile ukuze kuncishiswe ukuvela kwemigqa yokugeleza.Esinye isilinganiso esiphumelelayo sibeka isango engxenyeni encane enezindonga zensimbi, okusiza ukunciphisa ukwakheka kwemigqa yokugeleza.

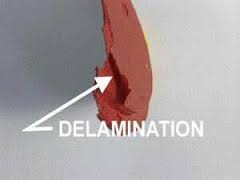

2. Ukwehliswa kobuso:

I-Delamination isho ukuhlukaniswa kwezingqimba ezincanyana ebusweni bengxenye, efana nezingubo ezixebukayo.Lesi simo senzeka ngenxa yokuba khona kokungcola okungahlanganisi ezintweni, okuholela emaphutheni asendaweni.I-Delamination nayo ingabangelwa ukuthembela ngokweqile kuma-ejenti akhulula isikhunta.

Ukubhekana nokuvimbela i-delamination, kuyanconywa ukuthi kukhuliswe izinga lokushisa kwesikhunta futhi kwandiswe uhlelo lokukhipha isikhunta ukuze kuncishiswe ukuthembela kuma-ejenti akhulula isikhunta, njengoba lawa ma-ejenti angaba nomthelela ekunciphiseni.Ukwengeza, ukomiswa kahle kwepulasitiki ngaphambi kokubunjwa kungasiza ekuvimbeleni ukubola.

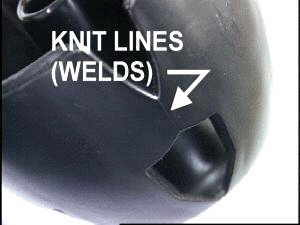

3. Imigqa ehlanganisiwe:

Imigqa eluniwe, eyaziwa nangokuthi imigqa yokushisela, yiziphambeko ezenzeka lapho ukugeleza okubili kwenhlaka encibilikisiwe kuhlangana njengoba kuhamba kumold geometry, ikakhulukazi ezindaweni ezinezimbobo.Lapho ipulasitiki igeleza futhi isonga ohlangothini ngalunye lwembobo, ukugeleza okubili kuhlangana.Uma izinga lokushisa le-resin encibilikisiwe lingalungile, ukugeleza okubili kungase kuhluleke ukuhlangana kahle, okuholela kumugqa wokushisela obonakalayo.Lo mugqa we-weld wehlisa amandla awo wonke kanye nokuqina kwengxenye.

Ukuze uvimbele inqubo yokuqiniswa ngaphambi kwesikhathi, kuyazuzisa ukwandisa izinga lokushisa le-resin encibilikisiwe.Ngaphezu kwalokho, ukuphakamisa isivinini somjovo kanye nokucindezela kungasiza futhi ekwehliseni ukuvela kwemigqa ehlanganisiwe.Ama-resin ane-viscosity ephansi kanye namaphoyinti ancibilikayo aphansi asengozini yokwakheka komugqa wokushisela ngesikhathi sokubunjwa komjovo.Ukwengeza, ukususa ama-partitions ekwakhiweni kwesikhunta kungaqeda ukwakheka kwemigqa ye-weld.

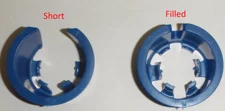

4. Amashothi amafushane:

Ukudubula okufushane kwenzeka lapho i-resin ihluleka ukugcwalisa ngokuphelele isikhunta, okuholela ezingxenyeni ezingaphelele nezingasetshenziswa.Izinto ezihlukahlukene zingabangela ukudubula okufushane ekubumbeni umjovo.Izimbangela ezivamile zihlanganisa ukugeleza okukhawulelwe ngaphakathi kwesikhunta, okungabalelwa kumasango amancane noma avinjiwe, amaphakethe omoya avaleleke, noma ukucindezela komjovo okwanele.I-viscosity yezinto ezibonakalayo kanye nezinga lokushisa lesikhunta nakho kungaba nomthelela ekuthwebuleni amafushane.

Ukuze uvimbele ukwenzeka kwesibhamu esifushane, kunenzuzo ukwandisa izinga lokushisa lesikhunta, njengoba lokhu kungathuthukisa ukugeleza kwe-resin.Ukwengeza, ukufaka umoya owengeziwe ekwakhiweni kwesikhunta kuvumela umoya ovaleleke ukuba ubaleke ngokuphumelelayo.Ngokubhekana nalezi zici, amathuba okuthi izithombe ezimfishane ekubumbeni umjovo angancishiswa.

5. Ukulwa:

I-Warping ekubumbeni umjovo isho ukusonteka okungahlosiwe noma ukugoba engxenyeni ebangelwa ukuncipha kokungalingani kwangaphakathi phakathi nenqubo yokupholisa.Lesi sici ngokuvamile sibangelwa ukupholisa kwesikhunta okungajwayelekile noma okungaguquki, okuholela ekukhiqizeni izingcindezi zangaphakathi ngaphakathi kwezinto. ukuze impahla iphole ngokufanayo.Ukugcina ukuqina kodonga olufanayo ekwakhiweni kwesikhunta kubalulekile ngenxa yezizathu ezimbalwa, okuhlanganisa ukwenza lula ukuhamba kahle kwepulasitiki endaweni yesikhunta ngendlela engaguquki. Ngokusebenzisa amasu okupholisa afanele nokuklama isikhunta esinogqinsi olufana nodonga, ubungozi bokulimala kwe-warpage ukubumba umjovo kungancishiswa, kuphumele ezingxenyeni ezisezingeni eliphezulu nezizinze ngobude.

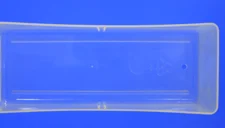

6. Ukundiza:

Ukukhubazeka kwe-Jetting ekubumbeni umjovo kungenzeka uma inqubo yokuqinisa ingalingani.I-Jetting kwenzeka lapho indiza yokuqala ye-resin ingena esikhunjeni futhi iqala ukuqina ngaphambi kokuba umgodi ugcwale ngokuphelele.Lokhu kubangela amaphethini okugeleza kwe-squiggly abonakalayo ebusweni bengxenye futhi kunciphisa amandla ayo.

Ukuze uvimbele ukukhubazeka kwe-jetting, kunconywa ukunciphisa ingcindezi yomjovo, uqinisekise ukugcwaliswa kancane kancane kwesikhunta.Ukwenyusa izinga lokushisa kwesikhunta kanye ne-resin kungasiza futhi ukuvimbela ukuqina ngaphambi kwesikhathi kwamajethi e-resin.Ukwengeza, ukubeka isango lomjovo ngendlela eqondisa ukuhamba kwezinto ngokusebenzisa i-eksisi emfushane yesikhunta kuyindlela ephumelelayo yokunciphisa i-jetting.

Ngokusebenzisa lezi zinyathelo, ubungozi bokulimala kwejethi ekubumbeni umjovo kungancishiswa, okuholela ekuthuthukisweni kwekhwalithi yendawo kanye namandla engxenye athuthukisiwe.

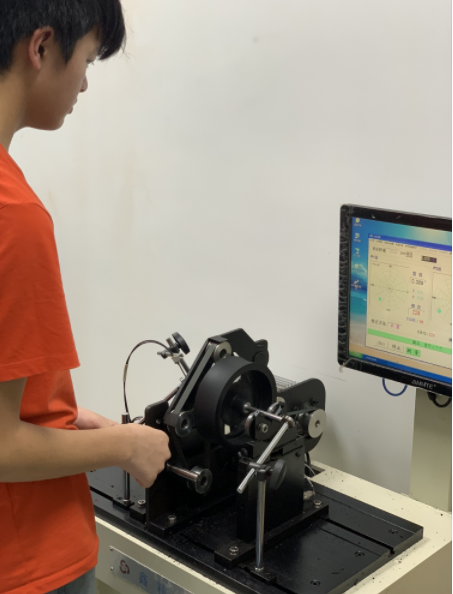

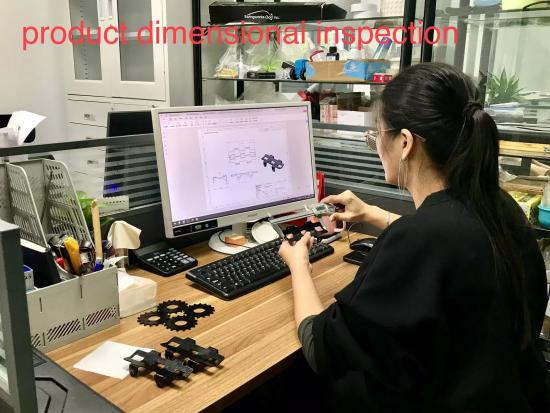

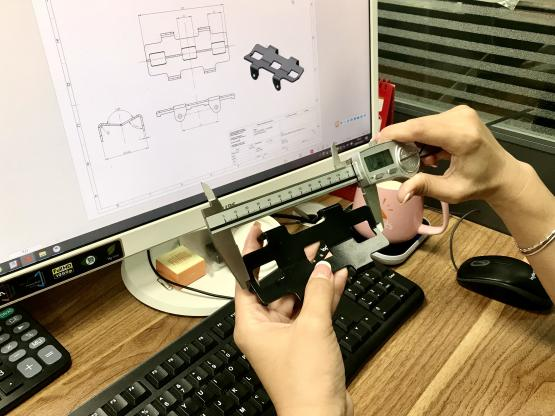

Inkampani yethu ithatha izinyathelo eziningi zokuvikela ukukhubazeka kokubumba umjovo futhi iqinisekise izingxenye ezibunjwe ngomjovo ezisezingeni eliphezulu.Izici ezibalulekile zifaka phakathi ukukhetha izinto zeprimiyamu, ukwakheka kwesikhunta okucophelelayo, ukulawulwa okunembile kwemingcele yenqubo, nokulawulwa kwekhwalithi okuqinile.Ithimba lethu liqeqeshwa ngobungcweti futhi liqhubeka lithuthukisa futhi lenze kahle inqubo yokukhiqiza.

Inkampani yethu ithatha izinyathelo eziningi zokuvikela ukukhubazeka kokubumba umjovo futhi iqinisekise izingxenye ezibunjwe ngomjovo ezisezingeni eliphezulu.Izici ezibalulekile zifaka phakathi ukukhetha izinto zeprimiyamu, ukwakheka kwesikhunta okucophelelayo, ukulawulwa okunembile kwemingcele yenqubo, nokulawulwa kwekhwalithi okuqinile.Ithimba lethu liqeqeshwa ngobungcweti futhi liqhubeka lithuthukisa futhi lenze kahle inqubo yokukhiqiza.

Inkampani yethu iqinisekisa ikhwalithi yomkhiqizo ngokulandela uhlelo lokuphathwa kwekhwalithi ye-ISO 9001.Senze uhlelo lokuphatha ikhwalithi oluphelele olunezinqubo nezinqubo ezisezingeni.Sikhuthaza ukubamba iqhaza kwabasebenzi futhi sihlinzeke ngokuqeqeshwa nemfundo.Ngalezi zinyathelo, siqinisekisa ukuthi imikhiqizo yethu ethunyelwe inekhwalithi enhle kakhulu futhi ihlangabezana nezidingo zamakhasimende.

Ukukhetha uzakwethu okhiqizayo ofana no-xiamenruicheng, onolwazi olubanzi ngokukhubazeka okujwayelekile kokubumba umjovo nokulungiswa kwakho, kungenza umthelela omkhulu kumphumela wephrojekthi yakho.Kungaba into enqumayo phakathi kokuthola izingxenye zekhwalithi ephezulu, ezilethwa ngeshejuli nangaphakathi kwesabelomali, noma ukubhekana nezinkinga ezifana nemigqa yokushisela, ijethi, iflash, ama-sink marks, namanye amaphutha.Ngaphandle kobungcweti bethu njengesitolo sokukhiqiza esifunwa kakhulu, siphinde sinikeze ngezinsizakalo zokubonisana nemiklamo kanye nokwenza kahle.Lokhu kuqinisekisa ukuthi sisiza iqembu ngalinye ekudaleni izingxenye ezisebenzayo, ezithandekayo, nezisebenza kahle kakhulu ngokusebenza kahle okukhulu.Thintana nathi namuhla ukuze uhlole izixazululo zethu ezibanzi zokubumba umjovo.

Isikhathi sokuthumela: Dec-15-2023