Izingxenye Zokujova Zepulasitiki

Imininingwane Yomkhiqizo

Ukuhlaziywa Kwephrojekthi:

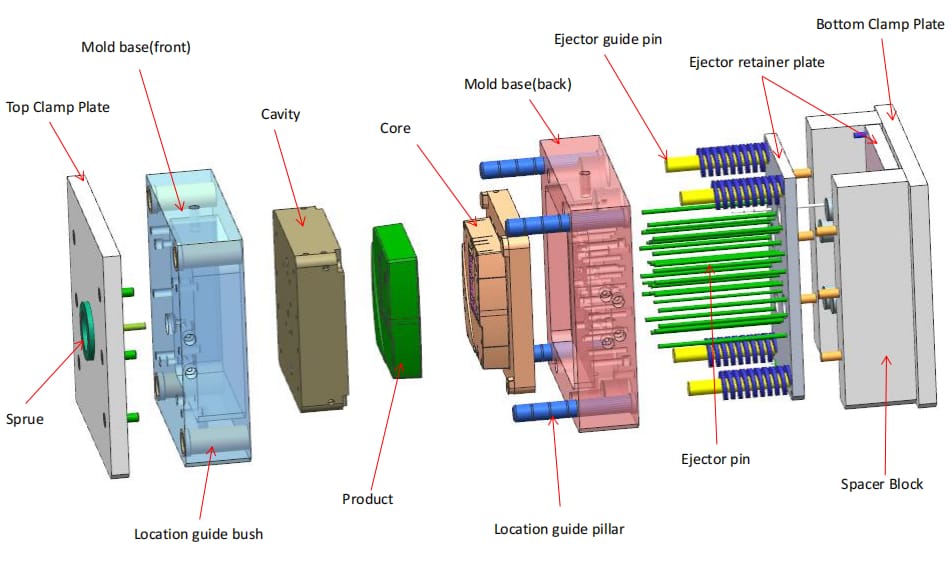

Ngemva kokuthola imidwebo ye-3d kanye nezidingo ezivela kumakhasimende, ithimba lethu lonjiniyela lizohlola izakhiwo zalo nobukhulu ukuze lixoxe futhi licabangele indlela yokuklama isikhunta (njengesango lomjovo, izikhonkwane, i-engeli yokusalungiswa njll.)

Inqubo Yokukhiqiza:

1. Ukubamba:

Ithuluzi liyavala, okukhombisa ukuqala komjikelezo wokubumba umjovo.

2. Umjovo:

Ama-polymer granules aqale omiswe futhi afakwe ku-hopper, bese efakwa emgqonyeni, lapho eshiswa ngesikhathi esifanayo, axutshwe futhi ahanjiswe ekubunjweni ngesikulufu esishintshashintshayo se-pitch.Ijiyomethri yesikulufu kanye nomgqomo kuthuthukisiwe ukusiza ukwakha ukucindezela kumazinga alungile nokuncibilikisa okokusebenza.

3. Ukupholisa:

Ngemuva kokuthi i-cavity yamathuluzi isigcwalisiwe, i-resin kufanele ivunyelwe ukupholisa.Amanzi ajikeleziswa ngethuluzi ukuze alondoloze izinga lokushisa elingaguquguquki ngenkathi okokusebenza kuqina.

4. Ukukhishwa

Njengoba impahla iphola, iphinde iqinise futhi ithathe isimo sesikhunta.Ekugcineni, isikhunta siyavuleka futhi ingxenye eqinile iphushwa ngaphandle izikhonkwane ze-ejector.Isikhunta sibe sesivala futhi inqubo iphinda.

5. Iphakheji

Imikhiqizo eqediwe izopakishwa kusetshenziswa isikhwama sepulasitiki bese ifakwa emakhathoni.Izidingo ezikhethekile zokupakisha, zingabuye zenziwe ngokwezifiso ngokuya ngezidingo zamakhasimende .Ukuze wonke umkhiqizo ulethwe usesimweni esihle.