Uyini umugqa wokushisela

Umugqa Welding ubizwa nangokuthi uphawu Welding, uphawu lokugeleza.Enqubweni yokubumba umjovo, lapho kusetshenziswa amasango amaningi noma izimbobo zikhona emgodini, noma ukufakwa kanye nemikhiqizo enezinguquko ezinkulu zobukhulu bokushuba, ukugeleza kokuncibilika kwepulasitiki kwenzeka esibunjeni ngezindlela ezingaphezu kwezi-2.Lapho izintambo ezimbili ezincibilikayo zihlangana, umugqa wokushisela uzokwakhiwa engxenyeni.Ukukhuluma ngokuqinile, cishe yonke imikhiqizo inemigqa yokushisela, futhi kunzima ukuyiqeda ngokuphelele, kodwa ukuyinciphisa, noma ukubenza bathuthele ezindaweni ezingabalulekile.

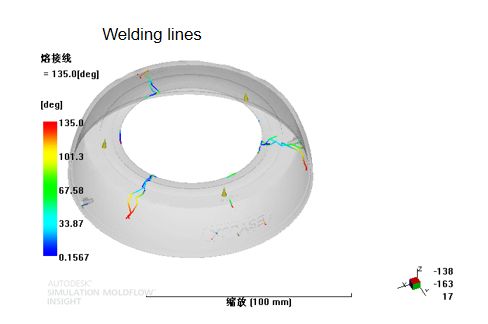

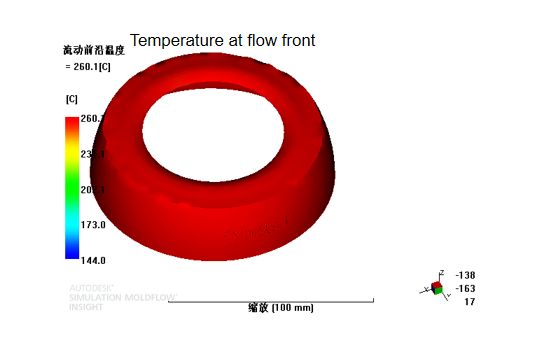

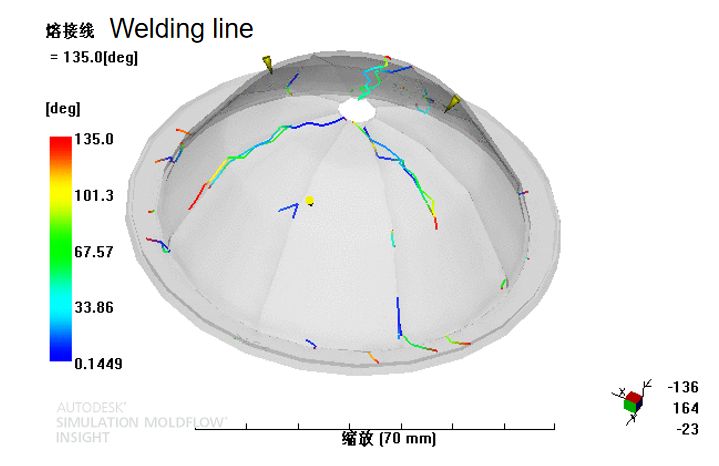

(Isibonelo Somugqa Welding)

Izizathu zokwakhiwa komugqa wokushisela

Ngesikhathi sokupholisa imicu emibili yepulasitiki endaweni yomugqa wokushisela, kuzoba nomoya ovaleleke phakathi kwemicu emibili yepulasitiki.Umoya ovalelekile uzovimbela umphumela wokusonteka wama-molecule e-polymer futhi wenze amaketanga wamangqamuzana ahlukane.

Indlela yokunciphisa umugqa wokushisela

Umklamo womkhiqizo kanye nomklamo wesikhunta

Uma ukubukeka nokusebenza komkhiqizo kubalulekile, ikhasimende kanye nomenzi wesikhunta kufanele basebenzisane, ukuze kuncishiswe umthelela wolayini wokushisela ngendlela engcono kakhulu.Ikhasimende/umklami womkhiqizo kufanele asize umenzi ekuqondeni umsebenzi ofanele womkhiqizo kanye nezici ezibalulekile zezimonyo.Khona-ke umklami wesikhunta kufanele acabangele umsebenzi wengxenye kanye nendlela ipulasitiki egcwalisa ngayo noma egeleza ngayo futhi ngokusebenzisa isikhunta ngesikhathi sesigaba sokuklama isikhunta, ecabangela ulwazi olufanele olunikezwa ikhasimende, okwandisa ukukhishwa komoya endaweni yomugqa we-welding futhi kuncishiswe. umoya ovalelwe.Kuphela uma ikhasimende nomenzi wesikhunta besebenza ndawonye ukuze baqonde umkhiqizo futhi basebenze ndawonye bangaqinisekisa ukuthi indawo enokucindezela okuncane kolayini wokushisela noma ibonakala ngendlela ebaluleke kakhulu .

Ukukhetha nokucutshungulwa kwezinto

Izinto ezihlukahlukene zinamandla ahlukene kakhulu we-welding line.Ezinye izinto zokuxhumana ezithambile zizwela i-shear futhi imigqa yokushisela ingase yenzeke ngisho noma izinga lokushisa elingaphambili lingaphazamiseki.Lokhu kungase kudinge ushintsho lwempahla ukuze kuxazululwe inkinga yomugqa wokushisela.

Ukucatshangelwa kwenqubo yokubumba umjovo

Iukubumba umjovoinqubo kungase futhi kuthinte amandla kanye isikhundla umugqa Welding.Ukushintshashintsha kwenqubo kwezinga lokushisa nokucindezela ngokuvamile kuzoba nomthelela othile kulayini wokushisela.

Uma kungenzeka, qiniseka ukuthi umugqa we-welding wakhiwe ngesikhathi sokuqala sokugcwalisa.Umugqa wokushisela owakhiwe ngesikhathi sokupakisha kanye nezigaba zokubamba ngokuvamile ziyinkinga.Ukwakhiwa kwemigqa ye-welding ngesikhathi sesigaba sokugcwalisa ngokuvamile kusiza ukwandisa izinga lokugcwalisa, ngaleyo ndlela ukunciphisa isikhathi sokugcwalisa nokwandisa izinga lokugunda.Lokhu kunciphisa i-viscosity ye-polymer ngesikhathi senqubo yokugcwalisa, okuholela ekuvuthweni okungcono kwamaketanga wamangqamuzana nokugcwalisa kalula.

Ngezinye izikhathi ukwandisa isikhathi sokupakisha noma ukucindezela ukubamba nakho kuzosiza.Uma ukubukeka kuyinkinga, izinga eliphansi lomjovo lingasiza, kodwa ngokuvamile izinga lokushisa eliphakeme lesikhunta lizohlinzeka ngemiphumela engcono.I-vacuum vesting iyithuluzi elinamandla elingaba usizo kakhulu ekusizeni ngezinkinga zokubukeka namandla.

Ukuze uthole okwengeziweukubumba umjovoulwazi, sicela ukhululekeXhumana nathi.

Isikhathi sokuthumela: Dec-01-2022