Ama-Silicones ayikilasi eliguquguqukayo lama-polymers eza ngezinhlobo ezahlukahlukene, anikeza amandla amakhulu okwenziwa ngokwezifiso ukuze ahlangabezane nezidingo eziqondile zomkhakha wezokwelapha kanye ne-aerospace.Izici zabo zibenza bakwazi ukwenza imisebenzi ehlukahlukene, njengokufaka uphawu, ukugcoba, nokufeza inqwaba yeminye imisebenzi.

Ukuguquguquka kwe-Silicone kubangelwa izici zayo eziyingqayizivele zomzimba nezomshini, eziyenza ibe yinto ebalulekile ezimbonini ezihlukahlukene.Lesi sihloko sizocubungula izici ezinhlanu ezijwayelekile kanyeusizo lwe-siliconefuthi uhlole iizigaba ezine eziyinhlokoizinto ze-silicone.Ukwengeza, sizoxoxa ngezindlela ezihlukene zokukhiqiza futhi sichaze ukuthi kungani i-silicone ingase ibe inketho efanelekile yezidingo zakho ezithile.

I-1.Ama-Silicone awaphenduli ngamakhemikhali futhi abonise ukungahambi kahle kwe-thermal.

Ukunqamula amaketanga e-silicon-oksijeni kuma-molecule e-silicone kudinga inani elibalulekile lamandla.Ngenxa yokumelana okuphezulu kwama-molecule e-silicone ukushintsha, amakhemikhali amaningi awanawo amandla anele okudala ukusabela kwamakhemikhali.Ngenxa yalokho, i-silicone ngokuvamile ayisebenzi ngamakhemikhali.Izibopho ezizinzile ku-silicone zinesibopho sezici zayo eziningi ezithandekayo.

Ama-silicone ngokuvamile abonisa ukuguquguquka okuphansi kwe-thermal ngenxa yesakhiwo samangqamuzana, okuvimbela ukusabalala kokudlidliza kokushisa phakathi kwama-molecule.Nakuba lesi sakhiwo singase sibe nenzuzo kwezinye izinhlelo zokusebenza, ezifana nama-oven mitts, kungaba umkhawulo kwezinye izimo lapho kudingeka khona ukudlulisa ukushisa okusebenzayo.Ukuze kuxazululwe le nkinga, izigcwalisi ze-thermal conductive zingafakwa ekwakhiweni kwe-silicone ukuze kuthuthukiswe ukudluliswa kokushisa futhi kuhlangabezane nezidingo zokusetshenziswa okuhlosiwe.

I-2.I-Silicone inobuthi obuphansi

I-silicone ngokuvamile ibhekwa njengento engenabungozi empilweni yomuntu.Zombili izinhlanganisela ze-silicone zebanga lokudla kanye nebanga lezokwelapha zigunyazwe yi-FDA ukuze zisetshenziswe ekuxhumaneni nokudla kanye nokufakwa isikhathi eside emzimbeni womuntu.Noma kunjalo, sicela ulandele izinkombandlela zomkhiqizi lapho usebenzisa imikhiqizo ye-silicone ukuze uqinisekise ukuphepha okukhulu.

3.I-Silicone inamandla amakhulu okuxosha amanzi

I-Silicone inekhwalithi eyingqayizivele eyaziwa ngokuthi i-hydrophobicity, okusho ukuthi inekhono lemvelo lokuxosha amanzi.Lokhu kubalulwe emaqenjini e-methyl axhunywe kuchungechunge lwe-silicon-oxygen polymer, okungezona i-polar ngokwemvelo futhi angenakho ukuhlobana kwama-molecule amanzi.Ngenxa yalokho, ama-molecule amanzi awakwazi ukusabalala futhi angene endaweni engaphezulu ye-silicone, futhi esikhundleni salokho, afaka ubuhlalu futhi asuke.Lesi sici esimangalisayo esinqanda amanzi, sihlanganiswe nekhono le-silicone ukwenza isibopho sokunamathela esiqinile esinezindawo ezihlukahlukene, senza imikhiqizo yokuvala i-silicone isebenze ngokukhethekileyo, enezimpawu ezingahlala amashumi eminyaka.

4.I-Silicone ingasebenza njenge-insulator kanye ne-conductor kagesi.

Irabha ye-Silicone ngokuvamile isebenza njengesivikelo ngenxa yokuntuleka kwayo kwama-electron amahhala okuphatha amashaji.Le khwalithi inenzuzo kakhulu ekusetshenzisweni okuhlukahlukene, ikakhulukazi emkhakheni wezokwelapha lapho ukufakwa kwesikhumba kubalulekile.Kodwa-ke, i-silicone ingashintshwa ukuze ihambise ugesi ngezinga elithile ezisetshenziswa njengama-gaskets nezihlangu ezimile.Lokhu kuguqulwa kuhilela ukufaka izigcwalisi ezifana nekhabhoni, isiliva, noma ezinye izinto ezithwalayo kumpahla ye-silicone.

I-5.I-Silicone inokumelana okuphezulu ne-organic compound solvents

I-silicone ngokuvamile iyakwazi ukumelana nokuchayeka kumakhemikhali amaningi ngenxa yokwakheka kwayo okungasasebenzi kanye namandla amancane angaphezulu.Noma kunjalo, izinto ezimbalwa ezikhethiwe ezingaphili, ikakhulukazi i-sulfuric egxilile kanye ne-hydrofluoric acid, zingalimaza ama-silicone.Mayelana nezinhlanganisela eziphilayo ezingase zisebenze njenge-sol, ama-silicone athambekele ekuwohlokeni ngemva kokuxhumana isikhathi eside nezinto ezifana ne-toluene, imimoya yamaminerali, uphethiloli, ne-carbon tetrachloride.

Ukusebenza kwe-silicone

Ukuguquguquka kweSilicone kuyenza ibe yinto ebalulekile ezimbonini ezahlukahlukene, kufaka phakathi:

* Ezezimoto: Ukumelana nokushisa okuphezulu kwe-silicone nokuqina kuyenza ibe yingxenye ekahle ekukhiqizeni izimoto.

* I-Aerospace: Izakhiwo ezinhle kakhulu zokuvikela i-silicone nokumelana namazinga okushisa aphakeme kakhulu kuyenza ibe into ebalulekile ekukhiqizweni kwezindiza.

* Izembatho: Izembatho ezenziwe nge-silicone zinikeza isiphetho esihlala isikhathi eside nesimelana namanzi ezindaweni ezihlukahlukene.

* Ukwakhiwa: Ama-Silicone sealants kanye ne-adhesives asetshenziswa ekwakheni isakhiwo ukuze kuqinisekiswe ukuthi amajoyini angangeni moya futhi angangeni manzi.

* I-Cookware: Izakhiwo ze-silicone ezikwazi ukumelana nokushisa ziyenza ibe into enhle kakhulu yezitsha zokupheka, njengamata okubhaka nama-spatula.

* Izinto zokuthambisa: Izithambisi ze-silicone zisetshenziswa ezintweni ezihlukahlukene, okuhlanganisa izinjini zezimoto, imishini yezimboni, nezinto zikagesi zasendlini.

* I-Electronics: Izakhiwo ezinhle kakhulu zokuvikela i-silicone ziyenza ibe into ebalulekile ezintweni zikagesi, njengamakhompiyutha, ama-smartphone, nomabonakude.

* Ukwenza isikhunta: Ukuguquguquka nokunemba kwe-Silicone kuyenza ibe yinto ekahle yokwakha isikhunta sezinhlelo zokusebenza ezihlukahlukene, okuhlanganisa imishini yezokwelapha nezingxenye zezimoto.

* Imithi nokuhlinzwa kwezimonyo: I-Silicone biocompatibility kanye nokuguquguquka kwezinto kuyenza ibe yinto ebalulekile ekufakweni kwezokwelapha, izitho zokwenziwa, kanye nokuhlinzwa kwezimonyo.

* Amathoyizi nezinto zokuzilibazisa: Ukuguquguquka nokuqina kweSilicone kuyenza into edumile yokwakha amathoyizi, imidlalo, nezinye izinto zokuzijabulisa.

Izinhlobo eziyinhloko zeSilicone

Izinhlobo ezine eziyinhloko zomzimba noma izinhlobo zemikhiqizo ye-silicone zibalwe ngezansi:

• Room-temperature Vulcanizing (RTV): Lawa ma-silicones azolapha, noma asethe, kuthempelesha yegumbi.Ngokuvamile zisetshenziselwa ukuhlanganisa nokuhlanganisa.Amafomu e-RTV-1 aqala ukuphulukiswa ngokushesha lapho ethintana nomswakama emoyeni.Ama-silicone e-RTV-2 eza njengezinhlanganisela ezimbili ezihlukene okufanele umsebenzisi wokugcina azihlanganise ukuze aqalise ukwelapha.Lokhu kwenza i-RTV-2 ivumelane nezimo kakhudlwana ezinhlelweni ezinjengokubumba nokunamathela.

• I-Liquid Silicone Rubber (LSR): I-LSR iqukethe isistimu yezingxenye ezimbili, nezinhlanganisela ezimbili ezihlanganisiwe ngesikhathi sokusetshenziswa.Ngokuvamile yelashwa ezingeni lokushisa eliphezulu, kusetshenziswa i-platinum catalyst.Kokubili inqubo yokubumba esetshenzisiwe kanye nezici zokugcina zomkhiqizo we-LSR zivumelana nezimo kuhlelo olubanzi lwezinhlelo zokusebenza.

• Irabha ye-Fluorosilicone (FSR): Ama-molecule e-FSR ahlanganisa amayunithi aphindayo omgogodla we-silicon-oxygen namanye amasayithi okubopha ahlala amanye amaqembu ama-molecule (amaqembu e-methyl kanye ne-fluoroalkyl).Lokhu kunikeza impahla ukumelana kangcono amafutha kanye namafutha.I-FSR idumile ngokuvala izinhlelo zokusebenza kuzilungiselelo zezindiza.

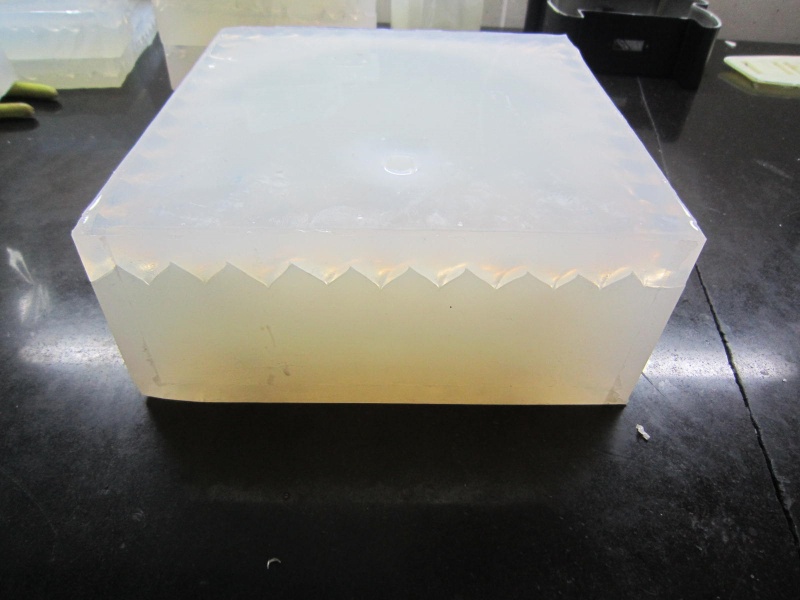

• I-High-Consistency Rubber (HCR): I-HCR, eyaziwa nangokuthi “irabha eqeda ukushisa,” iqukethe amaketango e-polymer e-molecular weight aphakeme kakhulu.Impahla eluhlaza ingahlalisa ama-fillers kanye nezithasiselo ukuze uthole izici ozifisayo.Ivamise ukufakwa ngendlela eselapheke kancane, ethi "gummy" egoqwe eshidini eliwugqinsi.Ilungele ukusetshenziswa emishinini ethile yezokwelapha, okuhlanganisa amashubhu, amabhaluni, namashidi.

I-Silicone iza ezimeni ezihlukene zomzimba, kusukela koketshezi kuya kokuqinile.Ci-ustomer ingakwazi ukwenza ngokwezifiso uhlobo oluhlukile lwe-silicone ngokomlingiswa womkhiqizo ukuze ivumelane nezidingo zemikhiqizo yokugcina.

Isifinyezo

I-athikili yahlola izici ezi-5 ze-silicone, yacacisa izici zayo zamakhemikhali nezomzimba, futhi yahlola izinhlobo ezihlukahlukene engazithatha ekusetshenzisweni kwezimboni.

Ukuze ufunde kabanzi mayelana ne-silicone,sicela usithinte.

Isikhathi sokuthumela: May-07-2024