Namuhla ukusetshenziswa kwezimpahla zepulasitiki ngokugcwele impilo yethu, kungakhathaliseki ukuthi yini yasendlini noma yezimboni.Kodwa ingabe uyazi ngempela ukwenza aingxenye yepulasitiki?Qhubeka ufunda, lesi sihloko sizokutshela.

Yini isikhunta sokujova

Ukubumba komjovo ngokuvamile okuchazwa ngokuthi i-polymer ye-thermoplastic kushisiswe ngaphezu kwendawo yayo yokuncibilika, okuholela ekuguquleni kwe-polymer eqinile ibe uketshezi oluncibilikisiwe olune-viscosity ephansi ngokunengqondo.Lokhu kuncibilika kuphoqeleka ngomshini, okungukuthi, kujovelwe, kube isikhunta esimo sento yokugcina oyifunayo.Ngokukhiqizwa kwemboni, ukubumba umjovo kungenye yezinqubo ezibaluleke kakhulu zokukhiqizwa kwezinto ngobuningi kusuka ku-thermoplastics.Izisebenzi zivame ukuthela izinto zokusetshenziswa zepulasitiki ezomile (njenge:ABDS,PP,TPU,PA66) emgqonyeni womshini wokubumba umjovo.Bese kuthi ngokwezidingo ezihlukene zomkhiqizo, amazinga okushisa ahlukene kanye nesivinini sokujova kwakhiwa.Bese usetha amazinga okushisa ahlukene kanye nesivinini sokujova ngokuya ngezidingo ezahlukene zomkhiqizo.Ngemuva kokupholisa kokugcina ukwenza umkhiqizo, kukhishwa iphinikhodi ye-ejector.

Kungani udinga isikhunta somjovo ngokwezifiso

1.Ubumfihlo bomkhiqizo kanye nokuvikeleka

Phakathi nenqubo yokukhishwa komkhiqizo, kuvame ukwenzeka ukuthi imikhiqizo eklanyelwe isikhathi eside idliwe ngaphambi kokuba ikhishwe.Lokhu kuvame ukubangelwa ukuthi amakhasimende asebenzisa isikhunta esenziwe ngomumo ukuze azihlanganise ngesikhathi sokuklama kanye nenqubo yokubumba umjovo, futhi abanalo isethi yabo yesikhunta.Uma wenza ngokwezifiso isethi yesikhunta esikhethekile semikhiqizo yakho, le nkinga ngeke isaba khona, ngoba sizogcina isikhunta ngesimiso sokuthi nguwe kuphela ongasisebenzisa, futhi wenze ukunakekelwa okujwayelekile kuzo ukuze kuzuze wena.Yisebenzise noma nini kamuva.

2.Ubunzima

Uma ukhetha ukwenza ngendlela oyifisayo isethi yesikhunta, imikhiqizo yakho ngeke isanqunyelwa ukwakheka nokubunjwa.Ngenxa yezinga eliphezulu lenkululeko ekwenzeni ngokwezifiso, ungakwazi ukuklama izakhiwo zomkhiqizo eziyinkimbinkimbi ngokwezidingo zakho esikhundleni sokuzihlanganisa ndawonye kusukela ekubunjweni okuningi.Lokhu kuzothuthukisa kakhulu ubuqotho nobuqotho bomkhiqizo.Ngobubanzi obubanzi bamanje bezicelo zokubunjwa komjovo kanye nemidwebo ye-3D, imikhiqizo oyiklamayo ingahluka kusuka kumikhiqizo yasendlini kuye kwezimboni.

3.Izindleko eziphansi

Ngokombono wokukhiqiza, ukwenza ngokwezifiso isikhunta kungase kudinge izindleko eziphakeme kunokusebenzisa isikhunta esenziwe ngomumo.Kodwa-ke, ngokombono wokukhiqiza, ukubumba umjovo kuyinqubo yokukhiqiza ngobuningi kanye nokusetshenziswa kwesikhathi eside kwesikhunta esenziwe ngomumo sokukhiqiza ukuhlanganisa.Izindleko ezilandelayo ziphakeme kakhulu, ngakho-ke uma ukhetha isikhunta esenziwe ngokwezifiso, ngeke udinge ukukhokha noma yini yesikhunta.

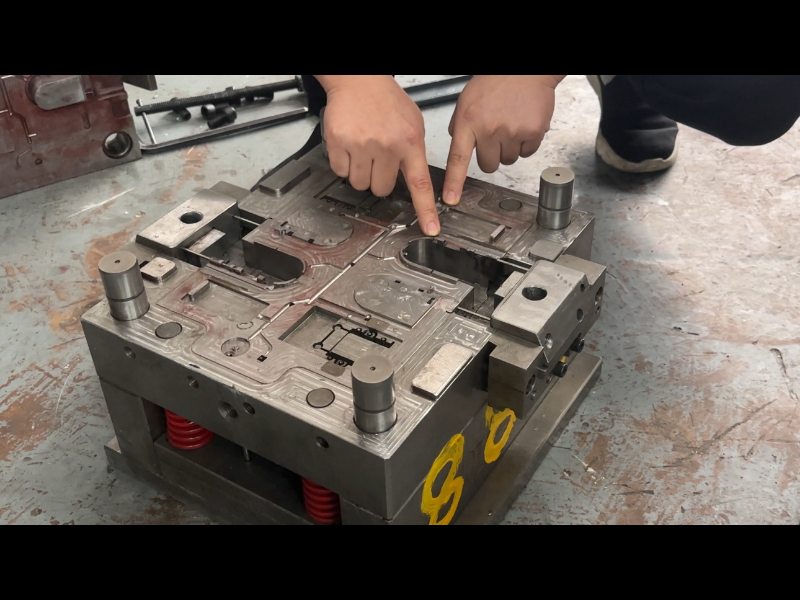

Indlela yokwenza isikhunta somjovo

Dala i-Mold nge-CAD

Ukuklanywa kwesikhunta kungenye yezinyathelo ezibaluleke kakhulu kule nqubo.Lesi yisinyathelo lapho kufanele unqume ukuthi ingxenye izobukeka kanjani, izokwenziwa kanjani nokuthi yiziphi izici ezoba nazo.Ukubumba umjovo kuyinqubo eyinkimbinkimbi, futhi isikhunta siyingxenye enkulu yalokho.Isikhunta sidinga ukukwazi ukumelana nokucindezela okuphezulu nokushisa kwenqubo yomjovo, kanye nokusetshenziswa okuphindaphindiwe.Kungakho kubalulekile ukuthola ukwakheka kwesikhunta kahle okokuqala.Isofthiwe ye-CAD ingakusiza ukuthi udale imodeli ye-3D ephelele yengxenye yakho ongayisebenzisa ukuze udale isikhunta.

I-3D Phrinta Isikhunta

Isinyathelo sokugcina ukuphrinta isikhunta usebenzisa iphrinta ye-3D.Lokhu kuzodala isikhunta sokugcina, esilingana nosayizi wangempela.Uma ungaqiniseki ukuthi ungakwenza kanjani lokhu, kunenqwaba yezifundo eziku-inthanethi ezingakusiza.Ungathola nezinsiza zokuphrinta ze-3D ezizokwenzela umsebenzi.Ukuphrinta isikhunta kuyisinyathelo esibalulekile, njengoba kuzoqinisekisa ukuthi umkhiqizo osuphelile usezingeni eliphezulu kakhulu.

Uma ufuna ukwazi okwengeziwe nge-design mold, ungafundaI-Mold Design kanye Nokukhiqiza Izingxenye Zepulasitiki

Inkinga evamile ekwenzeni isikhunta

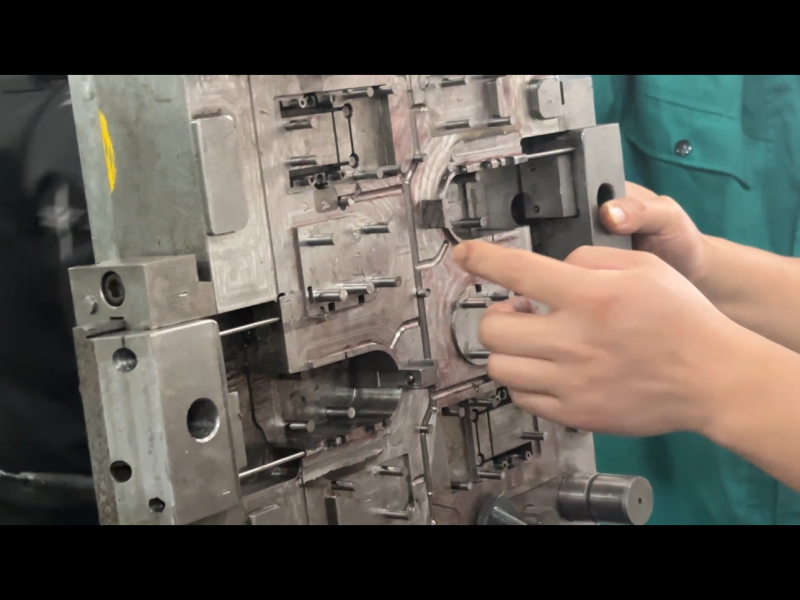

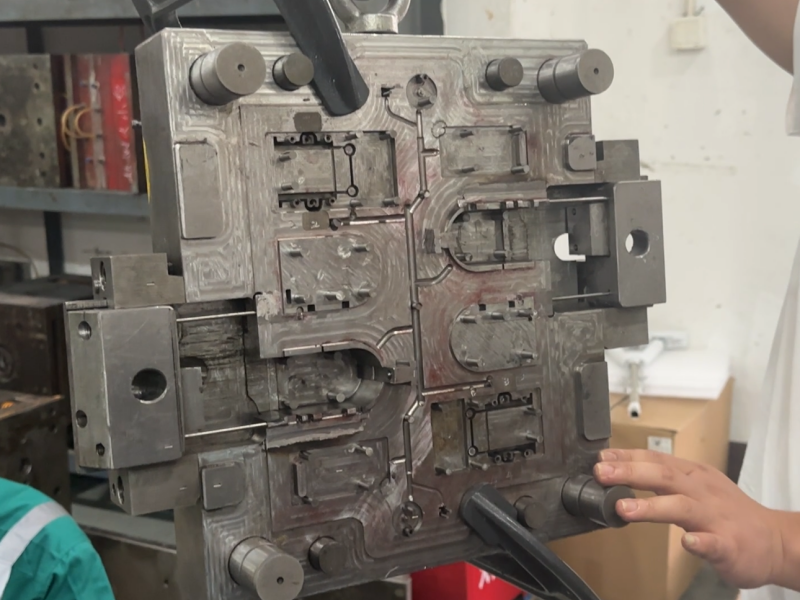

1.isilayidi

Uma isilayidi sihlanganiswa ngokuhlanganisa, asikwazi ukulingana ngokuphelele nesikhunta.Lapho isikhunta sivulwa futhi sivalwa, kulula ukubangela ukuba phezulu okuthambekele kuphuke.

2.umgudu wamanzi

Awukho umzila wokugeleza kwamanzi ohleliwe lapho uklama isikhunta, esivame ukuba nezinkinga zokupholisa umkhiqizo.Ngaphezu kwalokho, ngemva kokusetshenziswa isikhathi eside kwesikhunta, izinga lokushisa lesikhunta liyoba phezulu nangaphezulu, ekugcineni liholele ekuguquguqukeni komkhiqizo noma ukuphambuka kwesikhundla somgodi.

3.Ukugqokwa kwesikhunta

Phakathi nenqubo yokuklama isikhunta, ngenxa yokuthi azikho izikhala eziye zanezelwa ukuvumela amafutha ukuba agcobe isikhunta, i-coefficient ye-friction phakathi kwamabhulokhi ensimbi phakathi nenqubo yokugaya yayinkulu kakhulu, ibangela ukulimala kwesikhunta.

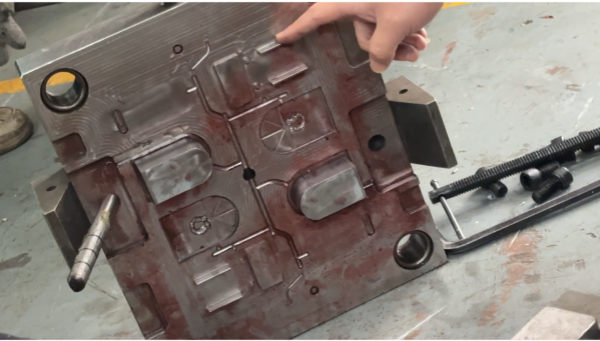

I-4.Ukunikezwa kwe-slot yomkhiqizo akunangqondo

Njengoba ukubunjwa komjovo kuhilela ukujova i-clinker yamanzi encibilikisiwe enezinga eliphezulu lokushisa eliphezulu emseleni wesikhunta ukuze kuphole okokugcina komkhiqizo, isikhunta semikhiqizo emikhulu sidinga ukuba seduze nendawo yokufaka iglu ukuze kuvinjwe izinga lokushisa ukuthi liphole ngenxa yebanga elide futhi ukungakwazi ukujova ngempumelelo esikhunjeni.Kodwa ukubunjwa kwemikhiqizo emincane kudinga ipulasitiki encane, ngakho-ke ama-grooves ngokuvamile aklanyelwe emaphethelweni esikhunta.

5.Insimbi yehlala esikhunjini sokuqala

Insimbi yokusala ekubunjweni kwasekuqaleni ayithathelwa indawo izinto ezifakiwe.Uma kwenzeka umonakalo kamuva, yonke ingxenye esele yomzimba wangempela idinga ukusikwa ngocingo bese iphinde ifakwe.

Uma ungathanda ukwazi olunye ulwazi oluhlobene mayelana nenqubo yokubumba umjovo noma ukwenziwa kwesikhunta, sicela ukhululekexhumana nethimba lethu lochwepheshe.

Isikhathi sokuthumela: Apr-18-2024