Gxumela esigabeni

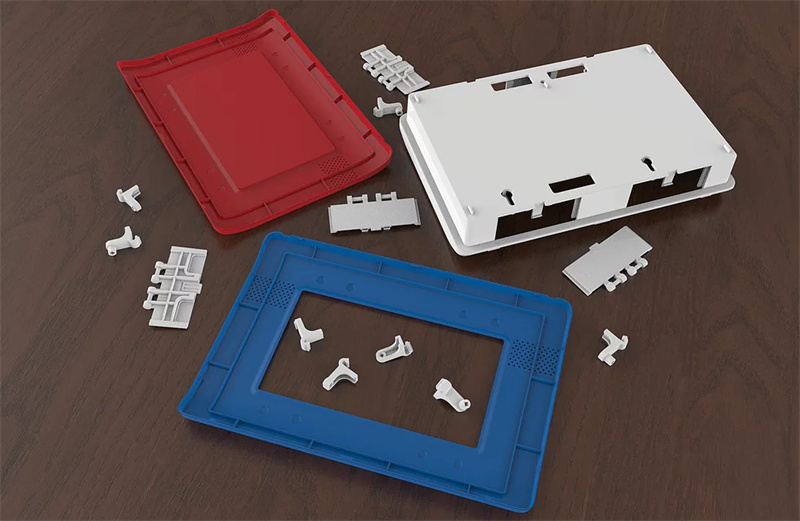

Inqubo yethu yokubumba umjovo wepulasitiki ikhiqiza ama-prototypes angokwezifiso kanye nezingxenye zokukhiqiza ezisetshenziswa ekugcineningokusheshaukuhola .Sisebenzisaithuluzi elithambileezinikezela ngamathuluzi akongayo kanye nemijikelezo yokukhiqiza esheshayo, kanye nesitoko mayelana100 ehlukene thermoplastic resins.

Izicelo ezijwayelekile zokubumba umjovo wepulasitiki:

- ukukhiqizwa kwevolumu ephansi

- uyagijima umshayeli

- ukuhlolwa okusebenzayo kanye ne-prototyping

I-Plastic Molding Amakhono

Imihlahlandlela yethu eyisisekelo yokubumba umjovo wepulasitiki ihlanganisa ukucatshangelwa kwedizayini okubalulekile ukusiza ukuthuthukisa ingxenye yesikhunta ikhono, ukuthuthukisa ukubukeka kwezimonyo, nokunciphisa isikhathi sokukhiqiza sisonke.

Emahoreni ambalwa ngemva kokuthola amamodeli e-3D CAD, sizokuthumelela idizayini yokuhlaziya ukwenziwa kwe-manufacturability (DFM) kanye namanani esikhathi sangempela . Kanye namanani, isilinganiso sethu sizophinde sibize noma yiziphi izici ezinzima ukuzenza ezisuselwe enqubweni yokukhiqiza. oyikhethile.Lokhu kungasukela kokunzima kuye kokwenza isikhunta kuya emigodini ejulile ezingxenyeni eziwumshini.

Izinto ze-Thermoplastic

Sinokhetho olubanzi lwezinto ezingaphezu kwe-100 ze-thermoplastic.Futhi uma ufuna ezinye izinto ongakhetha kuzo, hlola yethungezansi impahlaokwe-ABS, i-PC, i-PP, namanye amapulasitiki ajwayele ukubunjwa.

I-ABS

I-Acrylonitrile Butadiene Styrene (ABS) iyi-thermoplastic eyenziwe kusetshenziswa i-emulsion.Ngokuncipha kwayo okuqinile, okuguquguqukayo, okuphansi kwesikhunta (ukubekezelelana okuqinile), ukumelana namakhemikhali, amandla e-electroplating, i-opaque ngokwemvelo, izindleko eziphansi / eziphakathi..

Izinhlelo zokusebenza ezijwayelekile:Ezezimoto (amakhonsoli, amaphaneli, ukunquma, izinti), amabhokisi, amageji, izindlu namathoyizi.

I-TPV(Thermoplastic Vulcanisates)

I-TPV iyingxenye yomndeni wezinto ezibonakalayo we-TPE.Inezindawo eziseduze kakhulu nenjoloba ye-EPDM futhi inokumelana nezinga lokushisa eliphezulu kanye ne-elassity enhle kakhulu.

Izinhlelo zokusebenza ezijwayelekile: Izicelo zezimoto, izinto zasendlini, izinhlelo zokusebenza zokuvala

I-PEI(ULTEM)

I-PEI iyipulasitiki enemibala e-amber ekwazi ukumelana nezinga lokushisa eliphezulu namandla aphakeme kakhulu e-dielectric, okuyenza ibe yinhle kakhulu ezingxenyeni zensimbi yezokwelapha nezingxenye zokufakwa kukagesi.

Izinhlelo zokusebenza ezijwayelekile: Izingxenye zikagesi (izixhumi, amabhodi, amaswishi), amakhava, Izingxenye zensimbi yezokwelapha

I-Polycarbonate egcwele ingilazi iyinto eqinile futhi eqinile elungele ukusetshenziswa kwezimboni eziningi.

Izinhlelo zokusebenza ezijwayelekile: Pulleys, imishini yezokwelapha

I-PMMA(Acrylic)

PMMAiyi-polymer esobala ene-tensile enhle, ukumelana nokuklwebheka, kungaba njaloobalafuthiukucaca opticalin izindleko eziphansi/ezimaphakathi

Izinhlelo zokusebenza ezijwayelekile:izitendi zokubonisa, amafindo, amalensi, izindlu ezikhanyayo, amaphaneli, izibonisi, izimpawu, amashalofu, amathreyi

PP++ Ingilazi-Egcwele

I-Glass Filled PP Compound ikhiqizwa ngokuhlanganisa i-Polypropylene Homo-Polymer enezinga elihle le-Glass, enebanga elifanele losizo lokucubungula, isinzisi sokushisa kanye ne-Anti-oxidant.

Izinhlelo zokusebenza ezijwayelekile: izibambo zezindlu, izibambo

I-HDPE(Polyethylene - High Density)

I-HDPE iqinile futhi iqinile futhi ikwazi ukumelana namakhemikhali okuhle kakhulu, amandla aqine kakhulu, ukumelana nomthelela omkhulu kanye nephuzu eliphezulu lokuncibilika.

Izinhlelo zokusebenza ezijwayelekile: Izihlalo zezihlalo, izindlu, amakhava, izitsha namakepisi

I-LDPE(I-Polyethylene - Ukuminyana Okuphansi)

I-LDPE iyipulasitiki ethambile, eguquguqukayo, eqinile, futhi engasindi enokumelana nokugqwala okuhle ekubukekeni kwe-waxy kwemvelo kanye nezindleko eziphansi.

Izinhlelo zokusebenza ezijwayelekile:Iziqukathi, izikhwama, amashubhu, izinto zasekhishini, izindlu, amakhava

I-ASA(Acrylonitrile Styrene Acrylate)

I-ASA ingenye ye-ABS enokumelana nesimo sezulu okuthuthukisiwe.

Izinhlelo zokusebenza ezijwayelekile: Izingxenye zezimoto Izivalo, amaphaneli amakhulu

AMAHIPS(I-High Impact Polystyrene)

I-HIPS kulula ukuyibumba, igaywe kabusha, futhi inamandla amakhulu nokuqina.

Izinhlelo zokusebenza ezijwayelekile: Ukupakisha, izitsha, izibonisi

I-GPPS(I-Polystyrene - Inhloso evamile)

I-GPPS ishwabene, isobala kodwa inezindleko eziphansi.

Izinhlelo zokusebenza ezijwayelekile: Ukupakishwa kwezimonyo, amapeni

I-PPO(Polyphenylene oxide)

I-PPO inokuqina okuhle kobukhulu kanye nezakhiwo ezinhle zikagesi ezinokumuncwa kwamanzi okuphansi kanye nezindleko eziphezulu

Izinhlelo zokusebenza ezijwayelekile: Izimoto (izindlu, amaphaneli), izingxenye zikagesi, izindlu, izingxenye zamapayipi

I-PET (i-Polyethylene terephthalate)

I-PET iyinto evamile kakhulu yamabhodlela epulasitiki amanzi nezinye iziphuzo.Yaziwa nangokuthi i-polyester futhi isetshenziselwa ukwenza imicu yokwenziwa.

Izinhlelo zokusebenza ezijwayelekile:Amabhodlela amanzi epulasitiki, ukupakisha

I-PBT(Polybutylene Terephthalate)

I-PBT ifana nepulasitiki ye-PET futhi iyilungu lomndeni we-polyester.I-PBT ifaneleka kangcono ukwehlisa ukubumba nokusebenzisa amazinga okushisa.Inokushisa okuphezulu nokumelana namakhemikhali.

Izinhlelo zokusebenza ezijwayelekile: Izimoto (izihlungi, izibambo, amaphampu), ama-bearing, amakhamera, izingxenye zikagesi (izixhumi, izinzwa), amagiya, izindlu, amarola, amaswishi

I-PPA(Polyphthalamide)

I-PPA iqhathaniswa nenayiloni enokuqina okuphezulu, amandla, kanye nezakhiwo ezishisayo.Inokumelana okuhle nokukhasa kanye nokuzinza kwe-dimensional.

Izinhlelo zokusebenza ezijwayelekile: Izimoto, uwoyela negesi, izingxenye zamapayipi

I-PE(Polyethylene)

I-PE inephuzu elincibilikayo eliphansi, i-ductility ephezulu, amandla omthelela aphezulu, nokungqubuzana okuphansi.

Izinhlelo zokusebenza ezijwayelekile: Amafilimu, izikhwama, insulation electronic, amathoyizi.

PP(I-Polypropylene)

I-PP iku-lisisindo esinzimangeukumelana nokushisa, ukumelana namakhemikhali aphezulu, ukumelana nokuklwebhekafuthiukubukeka kwe-waxy yemveloleyoiqinile futhi iqinilein izindleko eziphansi.

Izinhlelo zokusebenza ezijwayelekile: Izimoto (amabhampa, amakhava, ukunquma), amabhodlela, amakepisi, amakhreyithi, izibambo, izindlu

I-PC/ABS

I-PC/ABS iyinhlanganisela ye-polycarbonate ne-ABSokungukuthi ukutholaizici ezinhle kakhulu zazo zombili izinto eziyisisekelo-ukumelana nokushisa nokuguquguquka.Le nhlanganisela iphinde icutshungulwe kalula ngesikhathi sokubunjwa komjovo kunanoma iyiphi yezinto eziyisisekelo.

Izinhlelo zokusebenza ezijwayelekile: Ezivalekile, amaphaneli amakhulu;

I-PBT+Ingilazi Igcwele

Ingilazi egcweleI-PBTiqine kakhulu futhi inamandla amakhulu okuqina kunezingaI-PBT.Iphinde ibe nokushisa okuphezulu nokumelana namakhemikhali.

Izinhlelo zokusebenza ezijwayelekile: izinhlelo zokusebenza zezimoto, izinhlelo zokusebenza ezivimba umlilo

I-PC(I-Polycarbonate)

PC kakhululukhuningeukumelana lokushisafuthiukuzinza kwe-dimensional,kungenziwaobalakodwa kuizindleko eziphezulu.

Izinhlelo zokusebenza ezijwayelekile:Izimoto (amaphaneli, amalensi, amaconsole), amabhodlela, iziqukathi, izindlu, amakhava okukhanya, izibonisi, izigqoko zokuzivikela nezihlangu

I-PVC(Polyvinyl Chloride)

I-PVC inobulukhuni obuphezulu, izakhiwo zokufakelwa kwemishini kanye nogesi.Ayizweli ngamakhemikhali oketshezini oluningi.

Izinhlelo zokusebenza ezijwayelekile: Iziqukathi zezokwelapha, izingxenye zokwakha, amapayipi, izintambo

I-PEEK(I-Polyetheretherketone)

I-PEEK inokushisa okuphezulu, amakhemikhali, nokumelana nemisebe nokumunca umswakama ophansi.

Izinhlelo zokusebenza ezijwayelekile:Izingxenye zezindiza, izixhumi zikagesi, ama-pump impeller, izimpawu

I-PPS(Polyphenylene Sulfidi)

I-PPS inamandla aphakeme kakhulu nokumelana nokushisa ngokugeleza okuhle nokuzinza kwe-dimensional.

Izinhlelo zokusebenza ezijwayelekile:izingxenye zesistimu kaphethiloli, imihlahlandlela, amaswishi, ukufakwa kukagesi, ulwelwesi, ukupakishwa

I-SAN (Styrene Acrylonitrile)

I-SAN(AS ) ingenye ye-Polystyrene ekwazi ukumelana nokushisa okuphezulu namakhemikhali futhi izinzile ngokwe-hydrolytically.

Izinhlelo zokusebenza ezijwayelekile: Izimpahla zasendlini, amafindo, amasirinji

I-TPE(Thermoplastic Elastomer)

I-TPE inokubukeka nomuzwa wento efana nerabha kodwa iyi-thermoplastic engancibilika kabusha.I-TPE inezinto ezinhle ezishisayo nokuzinza emazingeni okushisa ahlukahlukene angenziwa ngobulukhuni obuhlukene.

Izinhlelo zokusebenza ezijwayelekile: Izicelo zezimoto, izinto zasendlini

I-TPU(Thermoplastic polyurethane)

I-TPU iyinto enwebekayo ekwazi ukumelana kahle nowoyela, amafutha, nokuhuzuka.

Izinhlelo zokusebenza ezijwayelekile: Izinhlelo zokusebenza zemishini yezokwelapha, izinto zikagesi eziphathwayo

I-Acetal/POM (Delrin)

I-POMiyi-low-friction, lightweight thermoplasticeqinile futhi eqinile enokumelana nokukhathala okuhle kakhulu, ukumelana okuhle kakhulu kokunyakaza, ukumelana namakhemikhali nokumelana nomswakama kumhlophe opaque ngokwemvelo ngezindleko eziphansi/ezimaphakathi.

Izinhlelo zokusebenza ezijwayelekile: Amabhere, amakhamera, amagiya, izibambo, amarola, amarotha, imihlahlandlela yamaslayidi, amavalvu

Inayiloni - Ingilazi Igcwele & 6/6

Inayiloni 6/6 inamandla amakhulu emishini kanye nokuqina nokumelana nokukhathala, ukumelana namakhemikhali ekukhuphukeni okuphansi kanye nokungqubuzana okuphansi ngezindleko eziphakathi/eziphezulu.

Izinhlelo zokusebenza ezijwayelekile: izibambo, izinsimbi, izindlu ezincane, othayi be-zip & amagiya, ama-bushings

Inayiloni - Ingilazi Igcweleiqine kakhulu futhi inamandla angcono okuqina kunenylon ejwayelekile.Iphinde ibe ne-coefficient ephansi yokungqubuzana nokumelana nokushisa okuphezulu.

Izinhlelo zokusebenza ezijwayelekile: Amabhere, amawasha, indawo engasindi yezinsimbi lapho kufanele khona

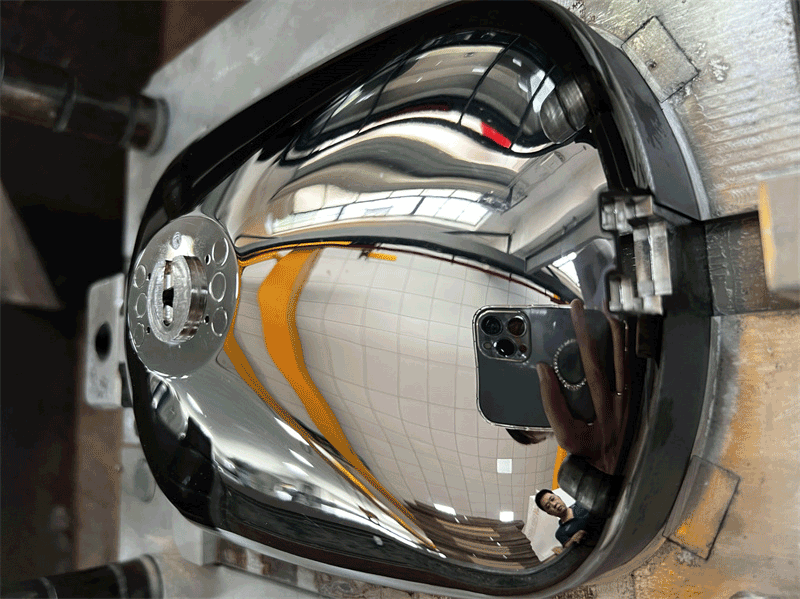

Izinketho Zokuqeda Ubuso

Izidingo ze-engeli esalungiswa zizohluka ngokuqeda okuceliwe.U-Xiamen Ruicheng,Izinga lemboniAmasistimu wokuhlukaniswa kwe-SPI kanye ne-VDIokuqediwe kuyatholakala.

Buka ikhasi lethu lemihlahlandlela yokuklama ukuze uthole imininingwane eyengeziwe

| Iyacwebezela | I-Semi-Glossy | I-Matte | Kuthunyiwe |

| I-SPI-A1 | I-SPI-B1 | I-SPI-C1 | I-SPI-D1 |

| I-SPI-A2 | I-SPI-B2 | I-SPI-C2 | I-SPI-D2 |

| I-SPI-A3 | I-SPI-B3 | I-SPI-C3 | I-SPI-D3 |

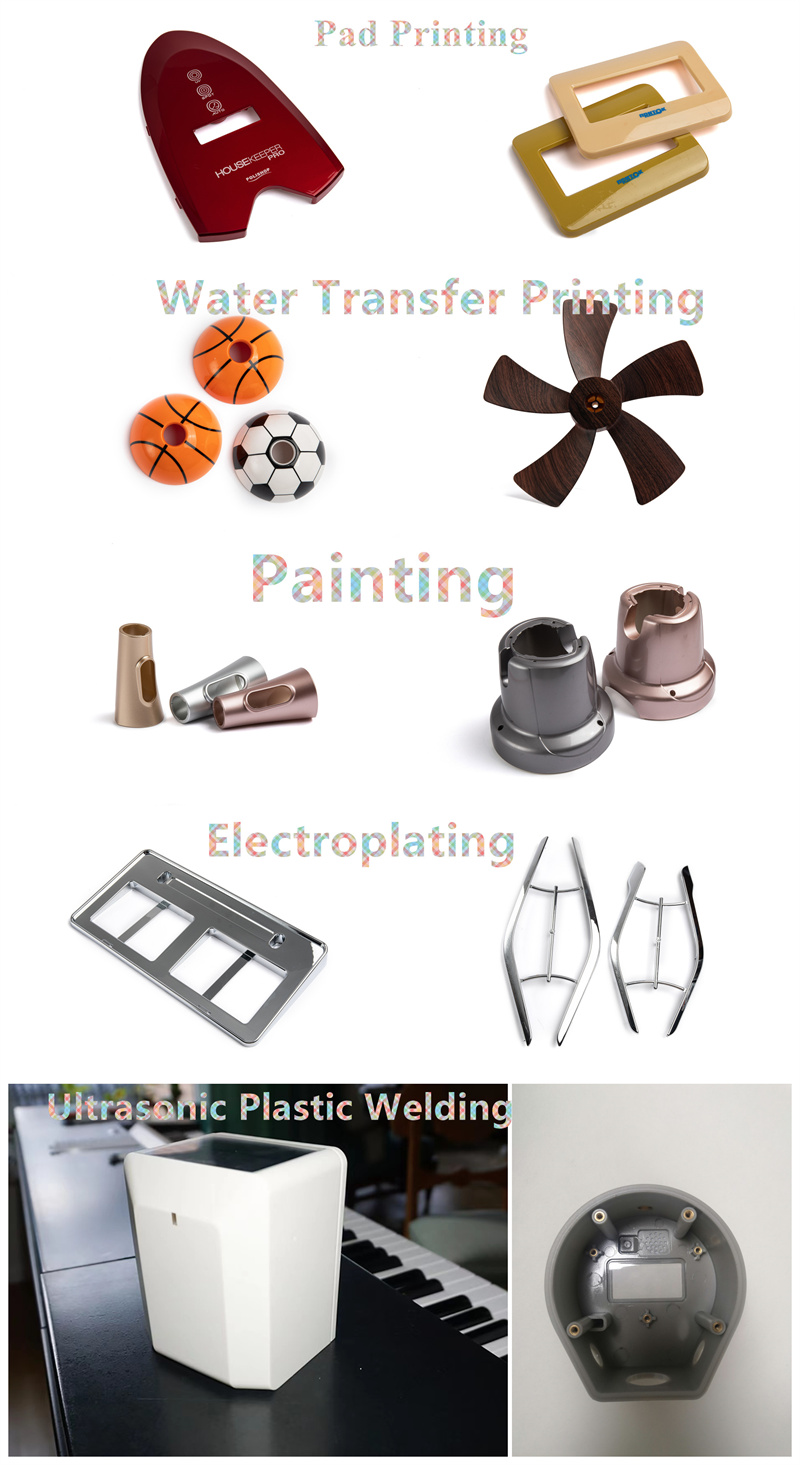

Imisebenzi Yesibili Ngemva Kokubumba Umjovo

Ukushisa Staking

Inqubo yokushisisa endaweni ingxenye yepulasitiki ukuze kuguqulwe futhi kufakwe enye ingxenye (njengokufaka okunentambo).

I-Laser Engraving

Umbhalo oqoshiwe noma umklamo usebenzisa i-laser.

Ukuphrinta Kwephedi

Ukuphrinta kwephedi kuyinqubo yokuphrinta engadlulisela isithombe/ilogo/umbhalo we-2D endaweni eyi-3D.

Ukudweba

I-Primer nejazi eliphezulu;imibala ejwayelekile noma i-Pantonenoma umbala we-RALukufanisa;ukufihla ubuso kuyatholakala;EMI (ithusi) upende.I-Glossy, Matte kanye ne-Smooth Texture konke kuyatholakala ukuze kusetshenziswe kukho

I-Electroplating

Kuyinqubo yokukhiqiza ukunameka kwensimbi ku-substrate eqinile ngokuncishiswa kwama-cations aleyo nsimbi ngokusebenzisa amandla kagesi aqondile.

I-Ultrasonic Plastic Welding

I-high frequency welder ikhiqiza ukushisa ukuze kuhlanganiswe noma kuguqule i-thermoplastics.

Kungani Usikhethele Isevisi Yokubumba Umjovo Wepulasitiki

Xiamen Ruichengihlinzeka ngezinsizakalo zokubumba ezithuthukisiwe zomjovo, ezinezixazululo ezimboza ukuqinisekiswa kwezinto, ukuklama kwamathuluzi, i-prototyping nokukhiqiza, ukuqeda, nokuqinisekiswa kwekhwalithi.Ithimba lethu lochwepheshe lizibophezele ekuletheni ukwesekwa kochwepheshe.Ngama-prototypes anembile nezingxenye zokukhiqiza,Xiamen Ruichengikusiza ukuthi ufinyelele imigomo yakho yokukhiqiza.

Izinqubo Zethu Zokubumba Umjovo

Xiamen RuichengInqubo yokubumba yomjovo ihlanganisa ukuhlaziya okunemininingwane yomklamo kanye nokukhiqizwa kwamathuluzi ochwepheshe besikhunta.Thatha ithuba lokuklama ngokucophelela nokwenza amathuluzi esikhunta sokujova ezingxenyeni zakho zepulasitiki zangokwezifiso.Sizosebenzisana nawe ukuze sibuyekeze isampula ye-T1 ngaphambi kokuthi siqale ukukhiqiza ivolumu ephansi.Umkhiqizo ngamunye uphela ngokuhlolwa okuqinile nokulawulwa kwekhwalithi ukuze uqinisekise ukuthi izingxenye zakho zihlangabezana nezindinganiso zamazwe ngamazwe.

Cela i-Quote esheshayo

Inkundla yethu yokucaphuna eku-inthanethi ingakusiza ukuthi uthole ikhotheshini esheshayo uma ucelwa ukuze onjiniyela bethu bakwazi ukuletha ikhotheshini kungakapheli amahora angama-24 ukuze uqalise ukukhiqiza.

Umbiko we-DFM

Idizayini yethu yokubuyekezwa kokukhiqiza isenza sikwazi ukuthola noma yikuphi ukukhubazeka noma okusikhathazayo kusengaphambili futhi sinikeze izincomo zedizayini engenzeka.

Ukuhlaziya Ukugeleza Kwesikhunta

Ukusebenzisa isofthiwe yokubikezela yokumodela kusivumela ukuthi sibone ukuthi into encibilikisiwe izoziphatha kanjani uma ingena esikhunjeni, okuvumela ukuthuthuka okwengeziwe kumklamo.

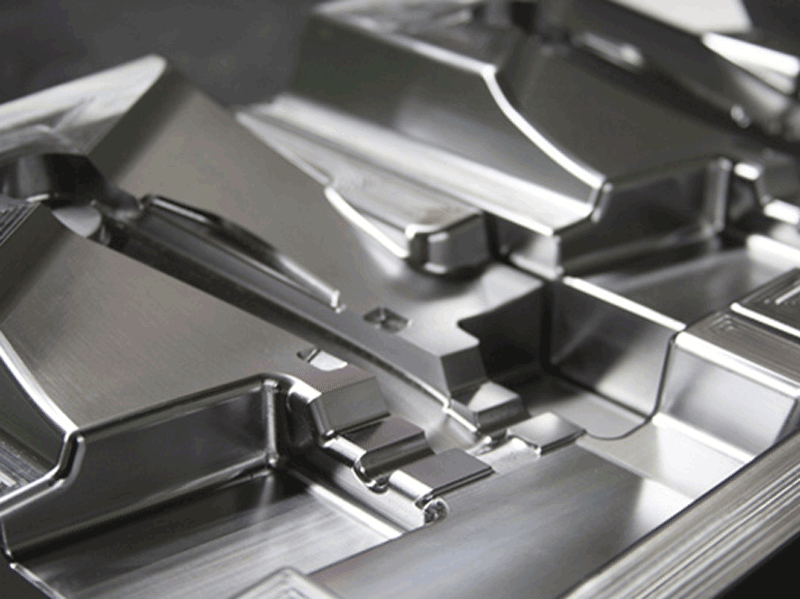

Isikhunta Tooling Production

Sifaka imishini yekhwalithi ephezulu ye-CNC ukusiza ukwakha isikhunta sokujova, siqinisekisa ukuthi isikhunta sikulungele ukusetshenziswa.

T1 Ukuhlolwa Kwesampula

Isampula ye-T1 izolethwa ukuze uyibuyekeze ngaphambi kokwenza izingxenye zepulasitiki ukuze uqinisekise ukunemba kanye nekhwalithi.

Ukukhiqizwa Kwevolumu Ephansi

Ngemuva kwesigaba sokukhiqiza isilingo, siqala ukukhiqizwa kwenqwaba ukuze sikhiqize izingxenye ngamanani asheshayo ukuze songe ngesikhathi nezindleko.

Ukuhlola Okuqinile

Silandela izindinganiso zamazwe ngamazwe zokubekezelela ukuze siqinisekise ukuthi izingxenye zethu zihlangabezana nemingcele yakho

Ukulethwa

Sisebenzisana nezinkampani zempahla ukuhlela ukulethwa okufika ngesikhathi endaweni yangakini.

Ukubunjwa komjovo kusuka ku-Prototyping kuya ekukhiqizeni

Ithuluzi elithambile

Thola impendulo yedizayini elula nokuqinisekisa ngokusebenzisa ikhwalithi ephezulu yamathuluzi Athambile.Dala amaqoqo amancane ezingxenye ezibunjiwe zepulasitiki ezinama-prototypes okubumba umjovo omuhle kakhulu.Sihamba phambili ekukhiqizeni isikhunta sesibonelo ezinsukwini ezimbalwa ukuze siqinisekise ukuthi wenza izivivinyo ezisebenzayo futhi uqinisekise inzalo yemakethe.(Ama-Soft Tooling Typical Quantities <2,000)

Ukukhiqiza Hard Tooling

Sakha isikhunta esiqinile sekhwalithi ephezulu sokukhiqiza izingxenye zepulasitiki eziphezulu.Ngamandla aphezulu, izinto zensimbi zamathuluzi aqinile, amathuluzi ethu okukhiqiza afaneleka ukukhiqiza izingxenye ezingamakhulu ezinkulungwane.Singashintsha izinto zokwakha kanye nezindlela zokwakha ngokuya ngezidingo zakho ezihlukile.

Izinzuzo Zokubumba Umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza ipulasitiki engakhiqiza izingxenye ezisezingeni eliphakeme esikalini.Ngokuvamile isetshenziselwa ukukhiqizwa kwevolumu ephansi kuya kwephezulu kodwa amathuluzi ethu e-aluminium angenza nokusebenza kwe-prototyping ukonga.

✔ Izindleko eziphansi ngamavolumu aphezulu

✔Ingxenye ehlukile yezimonyo nokuqedwa kwangaphezulu

✔Iyaphinda

✔Izingxenye eziyinkimbinkimbi

✔Izinga le-scrap eliphansi

✔Ukukhetha okukhulu kwe-thermoplastic kanye ne-thermoset materials

Izicelo zokubumba umjovo

Ukubumba umjovo kusetshenziswa kakhulu ukukhiqizwa kwengxenye yepulasitiki ezimbonini zezokwelapha, zabathengi, nezezimoto.Izingxenye ezijwayelekile zifaka:

✔ Izindlu

✔Abakaki

✔Amagiya

✔Izingxenye zokwelapha ezisetshenziswa kanye

✔Izixhumi zikagesi

✔Amasirinji

✔Izitsha

Izixhumanisi Ezengeziwe Nezinsiza

Umhlahlandlela wokuqeda umjovo wokubumba indawo yokuphothula - DFM

Ukuphela kwendawo yokubumba yomjovo ngokwezinhlelo zokuhlukaniswa kwe-SPI kanye ne-VDI - Ukucwebezela, i-semi-gloss, i-matte ne-textured surface finish.Okuqukethwe okufakwe kulesi sihloko Kuyini ukuphela kwendawo yokubumba komjovo?Kungani kufanele usebenzise ama-surface finishes ekubumbeni umjovo?Umjovo...

Ingabe Isikhunta Somjovo Wepulasitiki Ziyaguga Noma Zinokuphila Okulinganiselwe Kokukhiqiza?

Izibungu zokujova zepulasitiki zingaguga ngenxa yokungqubuzana noma ukuthintana okuphindaphindiwe phakathi kwezingxenye emijikelezweni eyizinkulungwane.I-Wear ithinta kakhulu amasango, amaslayidi, ama-ejectors nezinye izinto ezihambayo ngaphakathi kwesikhunta.Uma izingxenye zishelela noma zithinta i...

Ukukhetha Izinto Zokusetshenziswa Kwesikhunta Sakho Sokujova Wepulasitiki Ongokwezifiso

Njengoba kunezinhlobonhlobo zezinketho zezinto ezibonakalayo zokubumba ipulasitiki yangokwezifiso, kuyasiza kakhulu ukuthi onjiniyela bemikhiqizo bagxile emsebenzini oyinhloko kanye nendawo yokusebenza yezingxenye zabo.Lokhu kuvumela ukuncishiswa kwento efanele yomjovo wakho wangokwezifiso mo...