I-vacuum casting, eyaziwa nangokuthi i-silicone molding noma i-polyurethane casting, inqubo yokukhiqiza esetshenziselwa ukwakha amakhophi amaningi e-prototype noma ingxenye.Ivame ukuqashwa emkhakheni we-prototyping esheshayo kanye nokukhiqizwa kwevolumu ephansi.

Yiziphi izinyathelo zenqubo yokukhipha i-vacuum?

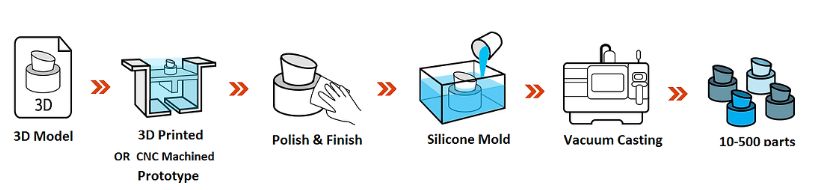

①Ukudalwa Kwemodeli Eyinhloko: Imodeli eyinhloko iqala ukukhiqizwa kusetshenziswa ukuphrinta kwe-3D, ukukhanda kwe-CNC, noma enye indlela efanelekile.Imodeli eyinhloko imelela umumo, ifomu, kanye nemininingwane yengxenye yokugcina noma umkhiqizo.

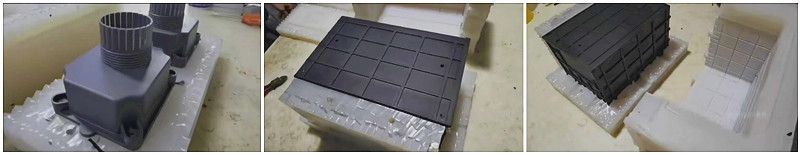

②Ukulungiselela Isikhunta: Isikhunta se-silicone sidalwa kusuka kumodeli eyinhloko.Imodeli eyinhloko ifakwe esitsheni, futhi i-silicone ewuketshezi ithululelwa phezu kwayo, ihlanganisa imodeli ngokuphelele.I-silicone ibe isivunyelwa ukwelapha, yenze isikhunta esiguquguqukayo nesiqinile.

③I-Mold Assembly: Uma isikhunta se-silicone seselaphekile, sinqunywa sibe ngama-halves, senze umgodi wokubumba.Ama-halves abe esehlanganiswa kabusha kusetshenziswa izici zokuqondanisa ukuze kuqinisekiswe ukuqondana okufanele ngesikhathi sokubunjwa.

④I-Material Casting: Izinto zokuphonsa ezifiswayo, ngokuvamile i-polyurethane resin, ziyalungiswa.Isikhunta sishiswe ngaphambi kokushisa okuqondile futhi sibekwe ekamelweni le-vacuum.Igumbi le-vacuum livaliwe, futhi i-vacuum isetshenziswa ukususa noma yimuphi umoya ovaleleke noma amagesi esikhunjini.

⑤Ukuthulula Nokuphulukisa: Izinto ezilungisiwe zokuphonsa zithululelwa emgodini wokukhunta ngembobo encane noma i-sprue.Ingcindezi ye-vacuum isiza ukudweba izinto ezibunjweni, iqinisekise ukugcwaliswa okufanele kanye nokunciphisa amabhamuza omoya.Isikhunta sibe sesishiywa singaphazanyiswa ukuze izinto zelaphe futhi ziqine.

⑥Ukususwa Nokuqedwa Kwesikhunta: Ngemva kokuba izinto ezibunjiwe seziphuluke ngokugcwele, isikhunta siyavulwa, bese ingxenye eyifaniso iyasuswa.Noma iyiphi impahla eyengeziwe noma ukukhanya kuyasikwa futhi kukhishwe.Ingxenye ingase idlule ezinyathelweni ezengeziwe zangemuva kokucubungula, njengokugcotshwa kwesihlabathi, ukupenda, noma ukuqedwa kwendawo, ukuze kuzuzwe ubuhle nokusebenza okufunayo.

Bona Yini Eyenza Ukusakazwa Kwevacuum Kudume Kakhulu

Izindleko-Ngempumelelo: Iqeda isidingo samathuluzi abizayo, njengesikhunta sokujova, esinganciphisa kakhulu izindleko zangaphambili.

Isivinini kanye nesikhathi sokuhola:Imijikelezo yokukhiqiza mifushane njengoba asikho isidingo sokusebenza kwamathuluzi okuyinkimbinkimbi noma ukusetha okubanzi.

Isivinini kanye nesikhathi sokuhola: Ukukhipha i-vacuum kunikeza izikhathi zokushintsha ngokushesha uma kuqhathaniswa nezinqubo zokukhiqiza ezivamile.

I-Surface Finish kanye ne-Aesthetics: Ukukhipha i-vacuum kungaletha ukuqedwa kwendawo ephezulu yekhwalithi ephezulu, kuphindaphinda ukubukeka nokuthungwa komkhiqizo wokugcina owufunayo.Ikhiqiza izingxenye ezinezindawo ezibushelelezi, ukunciphisa isidingo sokucubungula okubanzi noma ukuqeda.

Ungakhetha kanjani inqubo yokukhipha i-vacuum ngokuya ngesimo sangempela?

Ukukhetha inqubo yokukhipha i-vacuum efanele yesimo sakho esithile kuhilela ukucabangela izici ezimbalwa.Nazi ezinye izinto ezibalulekile ezingasiza ekuqondiseni isinqumo sakho:

Izidingo Zezinto Ezibalulekile: Qala ngokuhlonza izakhiwo ezibonakalayo ezidingekayo ku-prototype noma umkhiqizo wakho.Cabangela izici ezinjengokuqina, ukuguquguquka, ukubonakala, nokumelana nokushisa.I-vacuum casting isekela izinhlobonhlobo zezinto zokuphonsa, ezihlanganisa i-polyurethane (eqinile futhi eguquguqukayo), irabha ye-silicone, nama-resin acacile.Khetha inqubo yokukhipha i-vacuum engavumela izinketho zezinto ezifiselekayo.

Inani Nomthamo Wokukhiqiza: Thola inani lezingxenye okudingeka uzikhiqize.I-vacuum casting ifaneleka kahle kumavolumu okukhiqiza aphansi kuya kwamaphakathi.Uma udinga iqoqo elincane lama-prototypes noma ukukhiqizwa okulinganiselwe, ukukhishwa kwe-vacuum kungaba yisixazululo esingabizi kakhulu uma kuqhathaniswa nezinye izindlela zokukhiqiza ezifana nokubumba umjovo.

Ukuphindaphinda Kwemininingwane kanye Nokuqedwa Kwendawo: Hlola izinga lokuphindaphinda kwemininingwane nokuqedwa kwendawo edingekayo ezingxenyeni zakho.I-vacuum casting kwaziwa ngekhono layo lokukhiqiza kabusha imininingwane eyinkimbinkimbi, indlela yokwenza, nendlela engaphansi.Uma idizayini yakho ihlanganisa izici ezinhle noma amajiyometri ayinkimbinkimbi, ukusakaza kwe-vacuum kungaletha izifaniso ezinokwethembeka okuphezulu.Cabangela izinketho zokuqeda phezulu ezitholakalayo ngezinqubo ezihlukene zokukhipha i-vacuum ukuze uqinisekise ukuthi zihlangabezana nezidingo zakho.

Izinkinga Zesikhathi: Hlola umugqa wesikhathi wephrojekthi yakho kanye nezidingo zokushintsha.Ukukhipha i-vacuum ngokuvamile kunikeza izikhathi zokuhola ngokushesha uma kuqhathaniswa nezinqubo zokukhiqiza ezivamile.Cabangela isikhathi esidingekayo sokudala isikhunta, ukubunjwa, kanye nokucubungula ngemva kokucubungula.Abanye abahlinzeki besevisi banganikezela ngamasevisi asheshayo noma imishini yokusakaza eminingi, enganciphisa izikhathi zokuhola.Uma isikhathi sibalulekile, khetha inqubo yokukhipha i-vacuum engahlangabezana nomugqa wakho wesikhathi owuthandayo.

Izindleko Ukucatshangelwa: Hlaziya ibhajethi yakho kanye nezinkinga zezindleko.Ukukhipha i-vacuum kungaba yisixazululo esingabizi kakhulu sokukhiqiza ivolumu ephansi kanye ne-prototyping.Qhathanisa izindleko ezihlobene nokudala isikhunta, ukusetshenziswa kwezinto ezibonakalayo, kanye nokucubungula ngemva kokucubungula kubo bonke abahlinzeki besevisi yokukhipha isikhunta abahlukene.Qiniseka ukuthi ucabangela inani eliphelele nekhwalithi elethwa yinketho ngayinye.

Izidingo Ezengeziwe: Cabangela noma yiziphi izidingo ezengeziwe eziqondene nephrojekthi yakho.Isibonelo, uma udinga ukugoqa ngokweqile noma amandla okubumba, qinisekisa ukuthi inqubo yokukhipha i-vacuum ekhethiwe isekela izici ezinjalo.Cabangela noma yiziphi izitifiketi ezithile noma izindinganiso izingxenye zakho ezingase zidinge ukuthobelana nazo, njengezidingo ze-ISO noma ze-FDA.

Ngokucabangela lezi zici, ungenza isinqumo esinolwazi mayelana nenqubo yokukhipha i-vacuum efaneleka kakhulu isimo sakho esithile.Ukwengeza, ungathintana nenkampani yethu ngezinsizakalo zokukhipha i-vacuum ukuze uthole ukuqonda okwengeziwe nokuholwa.

Isikhathi sokuthumela: Dec-04-2023