I-Die casting inqubo yokuphonsa kwensimbi lapho insimbi encibilikisiwe, ngokuvamile ingxubevange engeyona insimbi njenge-aluminium, zinc, noma i-magnesium, ijovwa ngaphansi kwengcindezi ephezulu ibe isikhunta sensimbi esisebenziseka kabusha, esibizwa ngokuthi i-die.Idayi iklanyelwe ukwakha isimo esifiswayo somkhiqizo wokugcina.

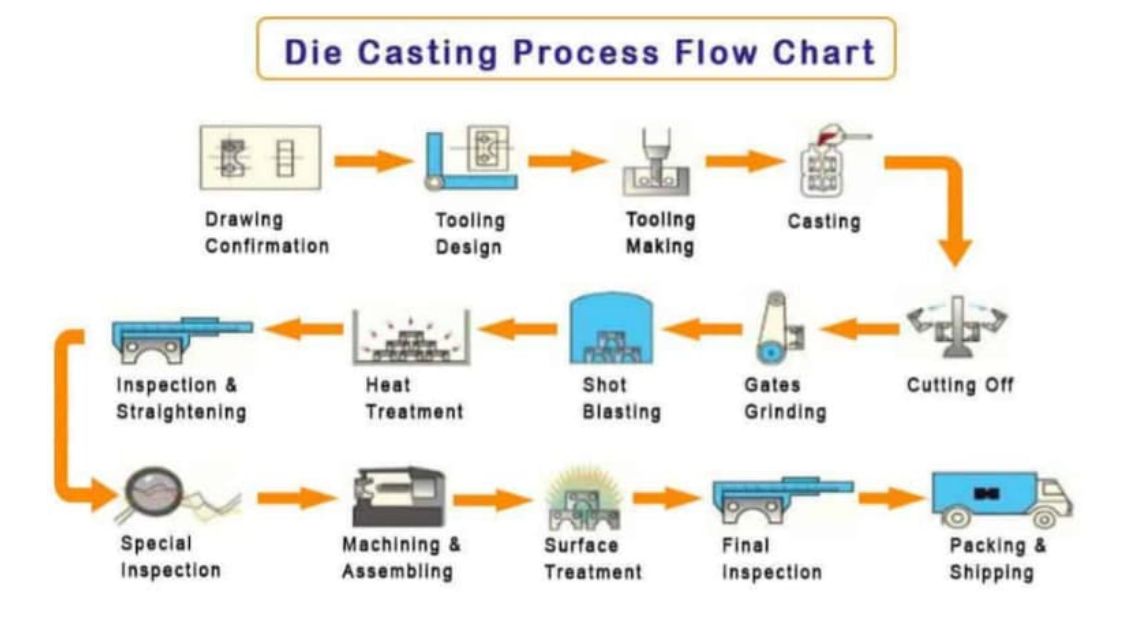

Yiziphi izinyathelo zenqubo yokufaka ukufa?

① Ukulungiselela Ukufa: I-Die, eyaziwa nangokuthi isikhunta, ilungiselelwa inqubo yokuphonsa.Idayi iqukethe amahhafu amabili, uhhafu ongashintshi (ikhava idayi) kanye nohhafu ogudlukayo (i-ejector die), okudala isimo esifiswayo somkhiqizo wokugcina.

②Ukuncibilikisa Insimbi: Insimbi ekhethiwe engeyona insimbi, njenge-aluminium, i-zinc, noma i-magnesium, incibilika esithandweni emazingeni okushisa aphezulu.Insimbi encibilikisiwe ifinyelela izinga lokushisa elifunayo lokubunjwa.

③Umjovo: Insimbi encibilikisiwe ijovelwa kufayi ngengcindezi ephezulu.I-piston noma i-plunger iphoqa insimbi encibilikisiwe ukuthi ingene emgodini we-die ngokusebenzisa i-sprue, i-runner, nesistimu yesango.Ukucindezela kusiza ukugcwalisa isikhunta ngokuphelele futhi uqinisekise ukuthi umumo oyifunayo ufinyelelwa.

④Ukuqiniswa: Uma insimbi encibilikisiwe isijovwe ku-die, ipholisa ngokushesha futhi iqine ngaphakathi kwe-die cavity.Inqubo yokupholisa ilawulwa ngokucophelela ukuze kuqinisekiswe ukuthi insimbi iqina ngokufanayo futhi ngaphandle kwamaphutha.

⑤Ukukhipha: Ngemuva kokuthi insimbi isiqinile futhi iphole ngokwanele, ama-die halfs ayavulwa, futhi ukusakaza, okwaziwa nangokuthi i-die casting, kukhishwa emgodini wokufa.Izikhonkwane zokukhipha noma amapuleti ejector asiza ukusunduza ukukhipha idayizi.

⑥Ukusikwa Nokuqeda: Ukulingwa kwe-die elikhishiwe kungase kube nezinto ezidlulele, ezaziwa njenge-flash, emaphethelweni ayo.Le nto eyeqile iyasikwa ukuze kuzuzwe umumo wokugcina ofisayo.Izinqubo zokuqeda ezengeziwe ezifana nomshini, ukusenta isihlabathi, noma ukupholishwa kungenziwa ukuze kucwengwe indawo kanye nokunemba kobukhulu bokusakaza.

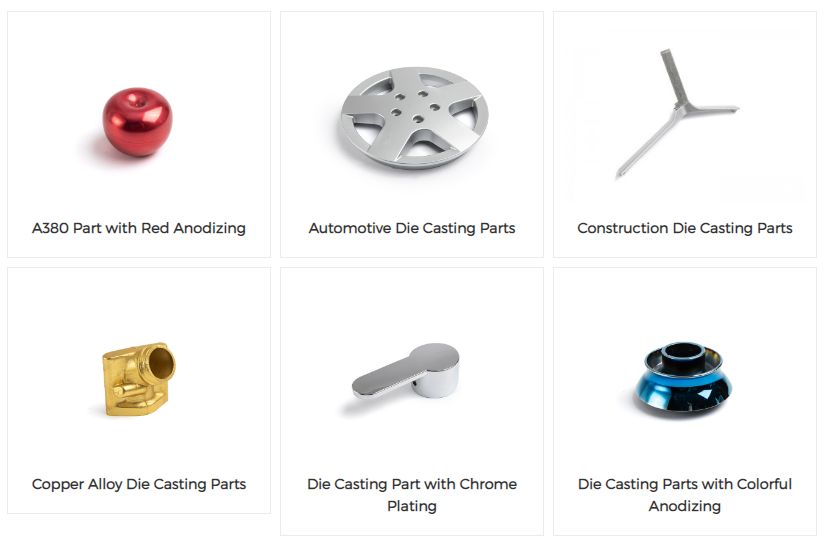

⑦ Ngemuva Kokwelashwa: Ngokuya ngezidingo ezithile kanye nokusetshenziswa kwe-die casting, izinqubo ezengeziwe zokwelashwa zingase zenziwe.Lokhu kungabandakanya ukwelashwa kokushisa, ukumbozwa kwendawo, ukupenda, nanoma yiziphi ezinye izinqubo zokuqeda ezidingekayo ukuze kuthuthukiswe izakhiwo noma ukubukeka kokulingisa.

Ungakhetha kanjani inqubo yokufaka ukufa ngokuya ngesimo sangempela?

Ukukhetha inqubo efanele yokukhipha ukufa kuncike ezintweni eziningana nokucatshangelwa okuhlobene nesimo sangempela.Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho ukhetha inqubo yokufaka ukufa:

Okubalulekile:Khomba uhlobo lwensimbi noma ingxubevange ezosetshenziselwa ukusakaza.Izinsimbi ezihlukene zinezici nezici ezihlukile, njengezinga lokushisa elincibilikayo, uketshezi oluningi, nezinga lokushwabana.Cabangela izidingo ezithile zengxenye noma umkhiqizo, njengamandla, isisindo, ukumelana nokugqwala, kanye ne-thermal conductivity, bese ukhetha inqubo yokufaka ifa efanele into ekhethiwe.

Ubunkimbinkimbi bengxenye:Hlola ubunkimbinkimbi bengxenye noma umkhiqizo ozokhiqizwa.Nquma ukuthi inomumo oyinkimbinkimbi, izindonga ezincane, ama-undercuts, noma izici zangaphakathi eziyinkimbinkimbi.Ezinye izinqubo ze-die casting, ezifana ne-high-pressure die casting (HPDC) noma i-multi-slide die casting, zifaneleka kangcono ukukhiqiza izingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile, kuyilapho ezinye zingase zifaneleke kakhulu imiklamo elula.

Ivolumu Yokukhiqiza:Cabangela umthamo wokukhiqiza odingekayo.Izinqubo ze-die casting zingahlukaniswa zibe yi-high-pressure die casting (HPDC) yokukhiqiza ivolumu ephezulu kanye ne-low-pressure die casting (LPDC) noma i-gravity die casting ngamavolumu aphansi.I-HPDC ivamise ukusebenza kahle kakhulu futhi iyonga kakhulu ekukhiqizeni okusezingeni eliphezulu, kuyilapho i-LPDC kanye ne-gravity die casting ifaneleka kangcono imigijimo emincane yokukhiqiza noma i-prototyping.

I-Surface Finish kanye Nokunemba:Linganisa isiphetho esifiselekayo esingaphezulu kanye nezidingo zokunemba kobukhulu bengxenye.Ezinye izinqubo zokulingisa izinto ezifayo, ezifana nokuminyanisa noma ukusakaza kwe-vacuum die, zinganikeza ukuqedwa okuthuthukisiwe kwendawo kanye nokubekezelelana okuqinile uma kuqhathaniswa nokusakazwa kwe-high-pressure kwendabuko.Lezi zinqubo zingakhethwa ezingxenyeni ezidinga ukushelela okukhethekile kwendawo noma ubukhulu obunembe.

Amathuluzi Nezisetshenziswa:Hlola ukutholakala kwamathuluzi nezinto zokusebenza ezidingekayo kunqubo yokufaka ukufa.Ezinye izinqubo zingadinga imishini ekhethekile, njengemishini yokukhipha ingcindezi ephezulu noma amasistimu okukhipha ingcindezi ephansi.Cabangela izindleko, isikhathi sokuhola, kanye nokuba nokwenzeka kokuthola noma ukulungisa amathuluzi adingekayo nezinto zokusebenza zenqubo ekhethiwe.

Izindleko nokusebenza kahle:Linganisa ukusebenza kahle kwezindleko nokusebenza kahle kwenqubo yokulingisa ukufa.Cabangela izici ezifana nezindleko zempahla, izindleko zamathuluzi, isikhathi somjikelezo wokukhiqiza, ukusetshenziswa kwamandla, nezimfuneko zabasebenzi.Qhathanisa izinzuzo nemikhawulo yezinqubo ezahlukene ukuze unqume inketho engabizi kakhulu yezidingo ezithile zokukhiqiza.

Ubungcweti nolwazi:Naka ulwazi nolwazi olutholakala enhlanganweni yakho noma kubahlinzeki be-die casting.Ezinye izinqubo zingadinga ulwazi olukhethekile, amakhono, nokusethwa kwemishini.Hlola amakhono nolwazi lwethimba lakho noma ozakwethu abangaba khona ukuze uqinisekise ukuqaliswa ngempumelelo kwenqubo ekhethiwe yokulingisa abashonile.

Ngokucubungula lezi zici ngokucophelela nangokubonisana nochwepheshe kulo mkhakha, ungenza isinqumo unolwazi futhi ukhethe inqubo efanele yokukhipha ukufa yesimo sakho esithile.

Uyemukelwa ku-Xiamen Ruicheng umphakeli onamandla kangaka ongabonisana naye, uzothola izeluleko zobungcweti!

Isikhathi sokuthumela: Feb-05-2024