ulungisa ukukhethwa kwezinto ezibalulekile kubalulekile ekudaleni ama-prototypes angokwezifiso kanye nezingxenye ngokusebenza komshini okufunayo, ukusebenza, kanye nobuhle.Kwa-Xiamen Richeng, sinikeza ulwazi oluyisisekelo lwezinto zokuphrinta ze-3D futhi sikusize ukhethe izinto ezifanele zengxenye yakho yokugcina.

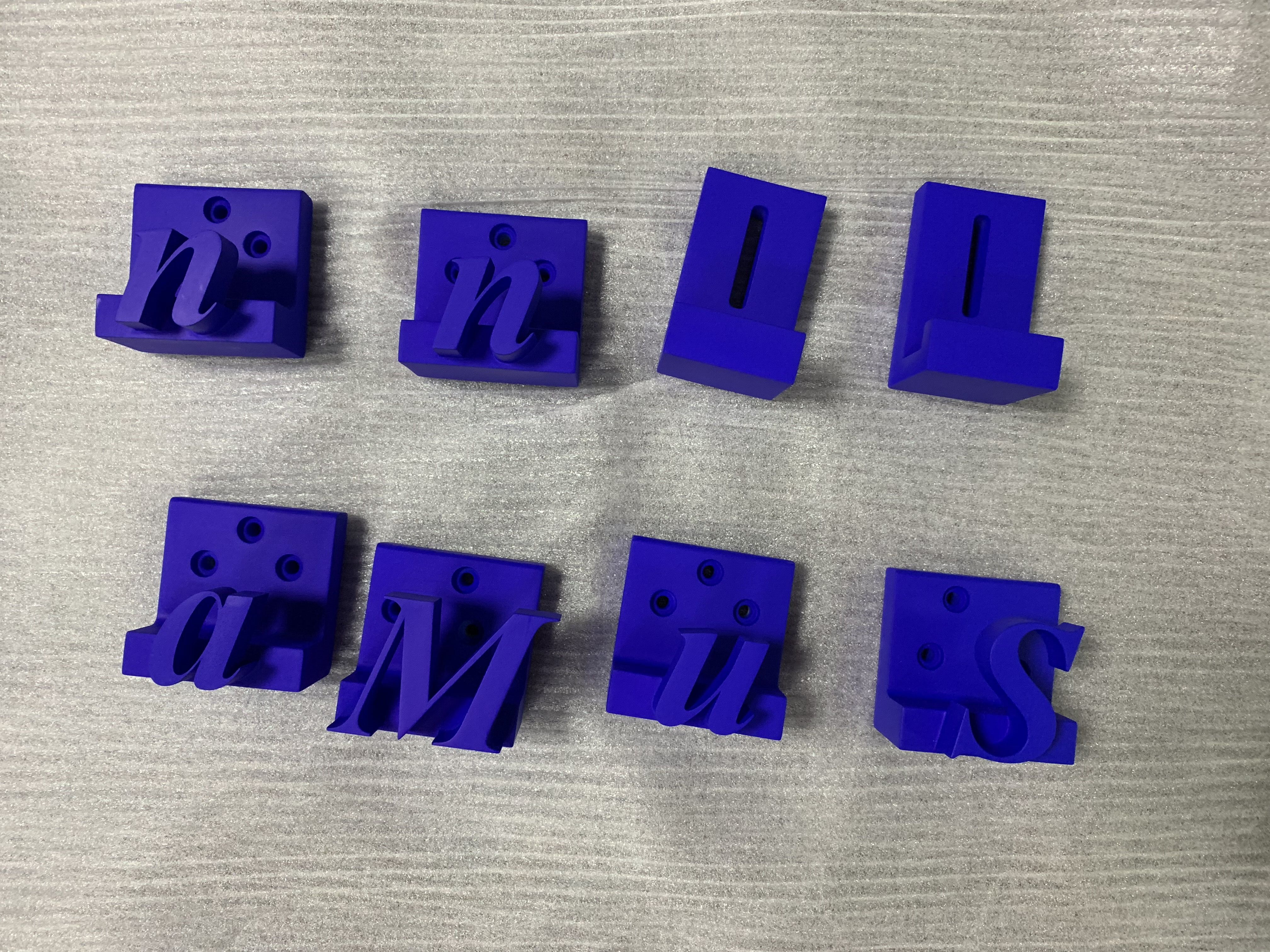

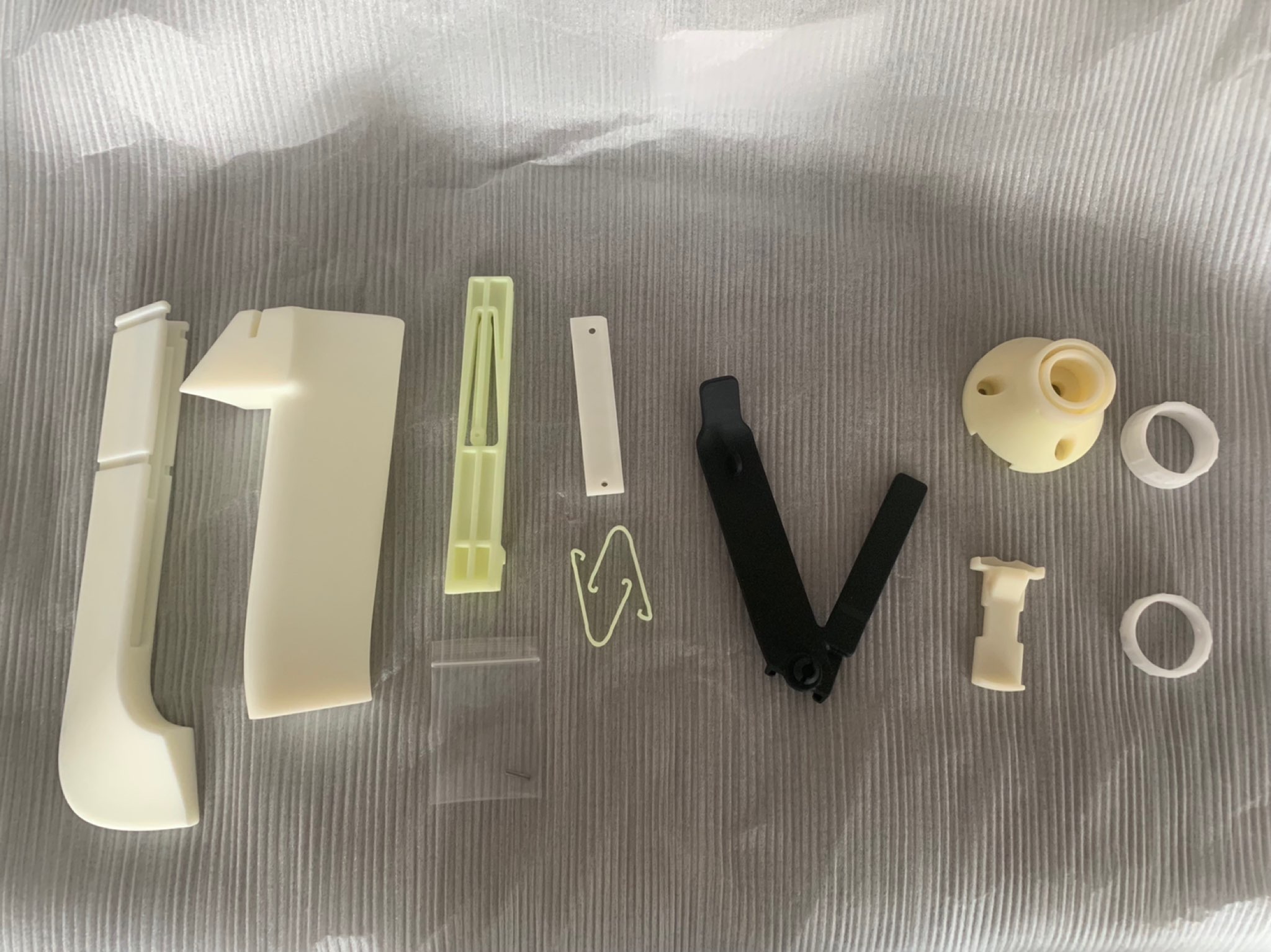

I-SLA

I-Stereolithography (SLA)ubuchwepheshe bokuphrinta be-3D obusebenzisa i-photosensitive resin kanye ne-laser ukudala ukunemba okuphezulu, izingxenye ezinemininingwane.Inqubo ihilela ukuphulukisa ungqimba lwe-resin ewuketshezi nge-laser beam, eqinisa i-resin futhi inamathele kungqimba lwangaphambilini.Isiteji sokwakha siyehliswa njengoba isendlalelo ngasinye selashwa kuze kuqedwe yonke ingxenye.

Izinzuzo:

Kumamodeli omqondo, ama-prototypes, nemiklamo eyinkimbinkimbi, i-SLA ingakhiqiza izingxenye ezinamajiyometri ayinkimbinkimbi kanye nokuqedwa okuhle kakhulu kwendawo uma kuqhathaniswa nezinye izinqubo zokukhiqiza ezingeziwe.Izindleko ziyaqhudelana.

Ububi:

Amandla ezingxenye ze-prototype angase angabi mahle njengalawo akhiqizwa nge-resin yebanga lobunjiniyela, ngakho izingxenye ezenziwe nge-SLA zinokusetshenziswa okulinganiselwe ekuhlolweni kokusebenza.I-fragile, njengoba imiklamo edinga amandla ngokuvamile yenziwa nge-CNC.I-CNC inezinto eziningi zokwakha ongakhetha kuzo futhi ingakhetha izinto ezahlukahlukene ngokuya ngezidingo zamandla.

Izinto ezisetshenziswa kakhulu zihlanganisa:

I-Godart® 8001 /Godart ®8228 /Godart® 8111X

Iphrojekthi yangempelasenzela ireferensi

I-SLS

I-Selective Laser Sintering (SLS) ubuchwepheshe bokuphrinta be-3D obusebenzisa i-laser enamandla amakhulu ukuze incibilike futhi ihlanganise izinto eziyimpuphu, njengenayiloni noma i-polyamide, ibe into eqinile.Inqubo ihilela ukusabalalisa ungqimba oluncane lwento eyimpuphu phezu kweplatifomu yokwakha bese usebenzisa i-laser ukuze ukhethe ngokukhetha (i-fuse) impushana ndawonye ngendlela yengxenye oyifunayo.Isiteji sokwakha siyehliswa njengoba isendlalelo ngasinye sifakwa, futhi inqubo iyaphindwa kuze kube yilapho yonke ingxenye isiqediwe.Ubuchwepheshe be-SLS bufanele ukukhiqiza amajiyometri ayinkimbinkimbi nezingxenye ezisebenzayo ezinamandla amakhulu.Isetshenziswa kabanzi ezimbonini ezahlukahlukene, kufaka phakathi i-aerospace, eyezimoto, nezokwelapha, ukwenza i-prototyping, ithuluzi, kanye nezingxenye ezisetshenziswa ekugcineni.

Izinzuzo:

Inayiloni ye-SLS inamandla angcono uma iqhathaniswa ne-SLA futhi ingacubungula izakhiwo eziyinkimbinkimbi.

Ububi:

Izingxenye zinokuthungwa kwe-granular noma kwesihlabathi, futhi ingaphezulu liqinile, lifanele imikhiqizo enezidingo eziphansi kanye nokunemba.

Izinto ezisetshenziswa kakhulu zihlanganisa:

PA12

Iphrojekthi yangempelasenzela ireferensi

I-SLM

I-Selective Laser Melting (SLM) ubuchwepheshe bokuphrinta be-3D obusebenzisa i-laser enamandla amakhulu ukuncibilikisa nokuhlanganisa izimpushana zensimbi ukuze kwakhiwe izingxenye eziqinile.

Izinzuzo:

Izinsimbi eziningi ziyatholakala ukuze zikhethwe futhi zingafinyelela izimo eziyinkimbinkimbi noma izici zangaphakathi.Isikhathi esifushane sokukhiqiza.

Ububi:

Uma kuqhathaniswa ne-SLA/SLS, intengo iphakeme ngokuqhathaniswa, indawo engaphezulu ilukhuni, futhi kuningi okwenziwa ngemva kokucubungula, futhi ukunemba akuphakeme.

Izinto ezisetshenziswa kakhulu zihlanganisa:

I-A1Si10Mg /316L /1.2709 / TC4 /GH4169

Iphrojekthi yangempelasenzela ireferensi

Eminye imibuzo ngobuchwepheshe bokuphrinta be-3D, sicela ukhululeke ukuxhumana nathi.

Isikhathi sokuthumela: Jun-19-2023