Ukuphela kwendawo yokubumba yomjovo ngokwezinhlelo zokuhlukaniswa kwe-SPI kanye ne-VDI - Ukucwebezela, i-semi-gloss, i-matte ne-textured surface finish.

Okuqukethwe okukhulunywa ngakho kulesi sihloko

Yiziphi iziqephu zokubumba ze-Injection?

Injection ukubumba surface finishibalulekile ekwakhiweni kwengxenye eyimpumelelo futhi isetshenziselwe izizathu zobuhle nokusebenza ezingxenyeni zokubumba umjovo wepulasitiki wemikhiqizo yobunjiniyela.Indawo engaphezulu ithuthukisa ukubukeka nomuzwa womkhiqizo njengoba inani elibonwayo kanye nekhwalithi yomkhiqizo kukhula ngokuqedwa kwendawo efanele.

Ikesi lePlastiki (Umthombo :XR USA Client)

Kungani kufanele usebenzise ama-surface finishes ekubumbeni umjovo?

Ukwandisa ingxenye yobuhle

Abaklami bezingxenye bangasebenzisa ukuthungwa ngezinjongo ezihlukahlukene zobuhle.Ukuthungwa kwendawo okubushelelezi noma okumatte kuthuthukisa ukubukeka kwayo futhi kuyinikeze isici esiphucuziwe.Iphinde ihlanganise amaphutha enziwa ukubumba komjovo, okufana nezimpawu zomshini wamathuluzi, izimpawu zokucwilisa, imigqa yokushisela, imigqa yokugeleza, nezimpawu zethunzi.Izingxenye ezinekhwalithi ephezulu kakhulu zikhanga kakhulu amakhasimende ngokombono webhizinisi.

Ukuthuthukisa ukusebenza kwengxenye

Ngaphandle kokucatshangelwa kobuhle okungena ekukhetheni indawo yokubumba umjovo, kukhona nokucatshangelwa okusebenzayo okubalulekile.

Idizayini ingase idinge ukubamba okuqinile ukuze kusebenze kahle.Ukuqedwa kwepulasitiki okuhlanganisiwe kuthuthukisa ikhwalithi yokubamba.Ngakho-ke imithi yokubumba indawo yomjovo isetshenziswa kaningi emikhiqizweni ekwazi ukumelana nokushelela.Isikhunta esithungwe singasiza futhi ekubalekeni kwamagesi avaleleke.

Ukuqedwa okubushelelezi kwe-SPI kungase kubangele upende ukuthi luxebuke.Kodwa-ke, indawo eqinile ingaqinisekisa ukuthi upende unamathela kangcono entweni ebunjiwe.Ukwelashwa kwendawo ye-SPI eyenziwe ngendwangu nakho kwandisa amandla nokuphepha kwengxenye.

Ukwakheka kwemvelo kunezinzuzo eziningana, okuhlanganisa:

- Ukugeleza kwepulasitiki-Lawa ma-crease angasuswa ngokungeza ukujiya okuthungwe ngenkathi kukhulisa amandla kanye nezakhiwo ezingasheleli.

- Ukubamba okuthuthukisiwe-Ukwengeza ukuthungwa kwengxenye kwenza ukuphatha kube lula, kukhulise ukusebenziseka nokuphepha ezinhlelweni ezithile.

- Ukunamathela ngopende-Upende unamathela ngokuqinile entweni eqoshiwe ngesikhathi sokubumba okulandelayo.

- Ukwenza ama-undercuts-Uma unengxenye engeke ihlale ifika engxenyeni ehambayo yesikhunta, ukuthumela umbhalo kunoma iyiphi indawo kungase kunikeze i-pu edingekayo.ll.

Ukucaciswa kokuphela kwethuluzi lesikhunta sokujova

Indlela ejwayeleke kakhulu yokucacisa izindawo zokubumba umjovo ukusebenzisaI-PIA (noma i-SPI), I-VDIfuthiIsikhunta-techizindinganiso.Abenzi bamathuluzi besikhunta sokujova, abakhiqizi nonjiniyela bokuklama emhlabeni wonke bayaqaphela la mazinga amathathu futhi amazinga e-PIA avame kakhulu futhi aziwa kabanzi ngokuthi “amabanga e-SPI”.

Ukuqeda okucwebezelayo - IBanga A - ukuphela kwedayimane

(I-SPI-AB Umjovo-wokubumba indawo yokuqeda)

Lezi ziqephu zebanga elithi “A” zibushelelezi, ziyacwebezela, futhi zibiza kakhulu.Lawa mabanga azodinga isikhunta sensimbi esiqinile, esigxotshwa kusetshenziswa amabanga ahlukahlukene we-diamond buff.Ngenxa yokunamathisela okusanhlamvu okucolisekileyo kanye nendlela yokupholisha ejikelezayo engahleliwe, ngeke ibe nokuthungwa okucacile futhi ihlakaze imisebe yokukhanya, inikeze isiphetho esicwebezelayo.Lokhu kubuye kubizwe ngokuthi “i-Diamond finish” noma “buff finish” noma “A finish”

| Qeda | I-SPI Standard | Qeda Indlela | Ukuqina Kobuso(Ra Value) |

| Ukuqedwa Okucwebezelayo Okuphakeme Kakhulu | A1 | 6000 Grit diamond buff | 0.012 ukuze 0.025 |

| I-High Glossy Finish | A2 | 3000 Grit diamond buff | 0.025 ukuze 0.05 |

| I-Glossy Ejwayelekile Qeda | A3 | 1200 Grit diamond buff | 0.05 kuya ku-o.1 |

Amamaki e-SPI acwebezelayo afanele imikhiqizo enobushelelezi obungaphezulu ngezizathu zezimonyo nokusebenza.Isibonelo, i-A2 iwukuphela kwedayimane elivame kakhulu elisetshenziswa embonini, okuholela ezingxenyeni ezinhle ezibukeka kahle ngokukhululwa okuhle.Ukwengeza, ama-surface finishes ebanga elithi “A” asetshenziswa ezingxenyeni zamehlo njengamalensi, izibuko, nama-visors.

Ukuqedwa kwe-semi-gloss - Ibanga B

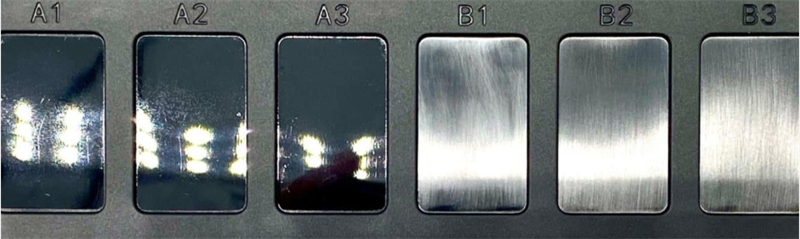

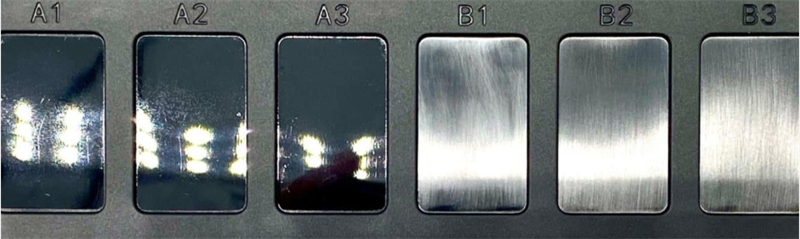

(umfanekiso 2.SPI-AB ukuqedwa kokubumba komjovo)

Lokhu kuqedwa kwe-semi-gloss kuhle kakhulu ekususeni amamachining, ukubumba, kanye namathuluzi ngezindleko ezizwakalayo zamathuluzi.Lezi ziphetho ezingaphezulu kukhiqizwa kusetshenziswa amabanga ahlukene ama-sandpaper asetshenziswa ngokunyakaza okuqondile, okunikeza iphethini yomugqa njengoba kukhonjisiwe kumfanekiso wesi-2.

| Qeda | I-SPI Standard | Qeda Indlela | Ukuqina Kobuso(Ra Value) |

| Fine Semi Glossy Qeda | B1 | 600 Grit Paper | 0.05 ukuze 0.1 |

| I-Medium Semi Glossy Qeda | B2 | 400 Grit Paper | 0.1 kuye ku-0.15 |

| Normal emi Glossy Qeda | B3 | 320 Grit Paper | 0.28 kuya ku-o.32 |

I-SPI(B 1-3) ukuqedwa kwe-semi-gloss surface kunganikeza ukubukeka okuhle futhi kususe izimpawu zamathuluzi zokubumba.Lezi zivame ukusetshenziswa ezingxenyeni ezingeyona ingxenye ebalulekile yokuhlobisa noma ebonakalayo yomkhiqizo.

Ukuphela kwe-Matte - Ibanga C

Lezi yizinto zokuqeda ezonga kakhulu nezithandwayo, ezipholishwa kusetshenziswa impushana yetshe elicolekileyo.Ngezinye izikhathi kuthiwa yi-stone finish, inikeza ukukhululwa okuhle futhi kusiza ukufihla izimpawu zomshini.IBanga C liphinde libe yisinyathelo sokuqala sokuqedwa kwamabanga A no-B.

| Qeda | I-SPI Standard | Qeda Indlela | Ukuqina Kobuso(Ra Value) |

| I-Medium Matte Qeda | C1 | 600 Itshe Elihlaza | 0.35 ukuze 0.4 |

| I-Medium Matte Qeda | C2 | 400 Grit Paper | 0.45 ukuze 0.55 |

| I-Matte Ejwayelekile Qeda | C3 | 320 Grit Paper | 0.63 ukuze 0.70 |

Ukuqedwa kombhalo - IBanga D

Inikeza ingxenye ukubukeka okubonakalayo kobuhle futhi isetshenziswa kakhulu ezingxenyeni zezimboni nasezimpahleni zabathengi.Lezi zifanele izingxenye ezingenazo izidingo ezithile ezibonakalayo.

| Qeda | I-SPI Standard | Qeda Indlela | Ukuqina Kobuso(Ra Value) |

| I-Satin Texture Qeda | D1 | 600 itshe ngaphambi kokuqhuma okomile kwengilazi ubuhlalu#11 | 0.8 kuye ku-1.0 |

| I-Dry Texture Qeda | D2 | Amatshe angama-400 ngaphambi kwengilazi yokuqhuma okomile #240 oxide | 1.0 kuye ku-2.8 |

| I-Rough Texture Qeda | D3 | 320 itshe ngaphambi kokuqhuma okomile #24 oxide | 3.2 kuye ku-18.0 |

Akekho owake wathi ukuklama nokukhiqiza izingxenye ezibunjiwe kulula.Umgomo wethu uwukuqeda ngokushesha nangezingxenye ezisezingeni eliphezulu.

Ukuqedwa kokubumba komjovo we-VDI

I-VDI 3400 Surface Finish (evame ukwaziwa ngokuthi i-VDI surface finish) isho izinga lokuthungwa kwesikhunta elibekwe ngu-Verein Deutscher Ingenieure (VDI), i-Society of German Engineers.I-VDI 3400 surface finish is ikakhulukazi icutshungulwa yi-Electrical Discharge Machining (EDM) lapho kwenziwa isikhunta.Kungenziwa futhi ngendlela yendabuko yokuthumela umbhalo (njengaku-SPI).Nakuba izindinganiso zibekwe umphakathi Wonjiniyela BaseJalimane zivame ukusetshenziswa phakathi kwabenzi bamathuluzi kuyo yonke indawo, okuhlanganisa iNyakatho Melika, iYurophu, ne-Asia.

Amanani e-VDI asekelwe kubukhulu obungaphezulu.Kusukela esithombeni, sibona ukuthungwa okuhlukile kwendawo engaphezulu enamanani ahlukahlukene obunzima obungaphezulu.

| Inani eliphakeme kakhulu lama-VDI | Incazelo | Izinhlelo zokusebenza | Ubulukhuni bobuso (Ra µm) |

| 12 | 600 Itshe | Izingxenye zokupholisha eziphansi | 0.40 |

| 15 | 400 Itshe | Izingxenye zokupholisha eziphansi | 0.56 |

| 18 | I-Dry Blast Glass Bead | I-Satin iphelile | 0.80 |

| 21 | I-Dry Blast # 240 oxide | Ukuqeda okubuhlungu | 1.12 |

| 24 | I-Dry Blast # 240 oxide | Ukuqeda okubuhlungu | 1.60 |

| 27 | I-Dry Blast # 240 oxide | Ukuqeda okubuhlungu | 2.24 |

| 30 | Ukuqhuma Okumile # 24 I-oksidi | Ukuqeda okubuhlungu | 3.15 |

| 33 | Ukuqhuma Okumile # 24 I-oksidi | Ukuqeda okubuhlungu | 4.50 |

| 36 | Ukuqhuma Okumile # 24 I-oksidi | Ukuqeda okubuhlungu | 6.30 |

| 39 | Ukuqhuma Okumile # 24 I-oksidi | Ukuqeda okubuhlungu | 9.00 |

| 42 | Ukuqhuma Okumile # 24 I-oksidi | Ukuqeda okubuhlungu | 12.50 |

| 45 | Ukuqhuma Okumile # 24 I-oksidi | Ukuqeda okubuhlungu | 18.00 |

Isiphetho

Ezigabeni ezimbili zokuqeda umjovo wokubumba umjovo, i-SPI grade A kanye no-B ithathwa njengeshelelayo enobushelelezi obusezingeni eliphansi kakhulu futhi ibiza kakhulu.Nakuba, uma ubuka indawo enobunzima, i-VDI 12, i-VDI yekhwalithi ephezulu kakhulu, ilingana nebanga le-SPI C.

Akekho owake wathi ukuklama nokukhiqiza izingxenye ezibunjiwe kulula.Umgomo wethu uwukuqeda ngokushesha nangezingxenye ezisezingeni eliphezulu.

Ungakhetha kanjani umjovo wokubumba umjovo ofanele?

Khetha indawo yokubumba yomjovo ngokucabangela umsebenzi wengxenye, into esetshenzisiwe, nezidingo ezibonakalayo.Iningi lezinto ezijwayelekile ezibunjwe ngomjovo wepulasitiki zingaba nezinhlobonhlobo zokuqeda.

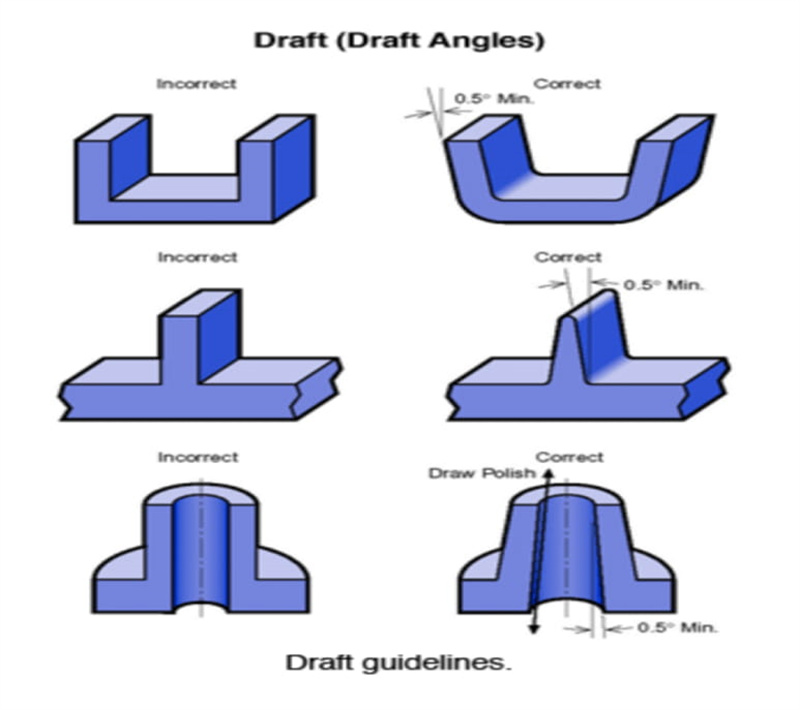

Ukukhethwa kokuqeda okungaphezulu kufanele kusungulwe esigabeni sokuqala sokuklama i-embodiment yomklamo womkhiqizo ngoba indawo engaphezulu ilawula ukukhethwa kwempahla kanye ne-engeli yokusalungiswa, okunomthelela ezindlekweni zamathuluzi.Isibonelo, inkambo noma isiphetho esibhaliwe sidinga i-engeli yokusalungiswa ebaluleke kakhulu ukuze ingxenye ikhishwe ekubunjweni.

Ngakho-ke yiziphi izici eziyinhloko okufanele uzicabangele lapho ukhetha isiphetho esingaphezulu samapulasitiki okubumba umjovo?

Gloss finish Grade A (Umthombo:XR USA Client)

Izindleko zamathuluzi

Ukuqedwa kwendawo kanye nokokusebenza kunethonya elikhulu ekwakhiweni kwethuluzi nezindleko, ngakho-ke cabangela futhi uhlole ukusebenza ngokuya kwendawo kusenesikhathi edizayini yokufanisa.Uma isiphetho esingaphezulu sibalulekile ekusebenzeni kwayo, cabangela ukuphela kwendawo ezigabeni zomqondo zomklamo womkhiqizo.

Izingxenye eziningi zenqubo yokubumba umjovo zenziwe ngokuzenzakalelayo, kodwa ukupholisha kuyinto ehlukile.Yisimo esilula kuphela esingapholishwa ngokuzenzakalela.Ama-Polishers manje anemishini engcono kanye nezinto zokusebenza okufanele asebenze ngazo, kodwa inqubo isalokhu idinga abasebenzi abaningi.

I-engeli yokusalungiswa

Izingxenye Eziningi Zidinga I-engeli Esalungiswa engu-1½ ukuya ku-2 Degrees

Lona umthetho wesithupha osebenza ezingxenyeni ezibunjiwe ezinokujula okungafika kumayintshi angu-2.Ngalo sayizi, okusalungiswa okungaba amadigri angu-1½ kwanele ukuze kukhululwe kalula izingxenye esikhunjeni.Lokhu kusiza ukuvimbela ukulimala ezingxenyeni lapho impahla ye-thermoplastic incipha.

Ithuluzi le-Mold material

Ithuluzi lesikhunta lithonya kakhulu ubushelelezi bobuso bokubumba umjovo.Isikhunta singenziwa ngezinsimbi ezihlukahlukene, nakuba insimbi ne-aluminium kuyizinto ezithandwa kakhulu.Imiphumela yalezi zinsimbi ezimbili ezingxenyeni zepulasitiki ezibunjiwe ihluke kakhulu.

Ngokuvamile, insimbi yamathuluzi eqinile ingakhiqiza ukuqedwa kwepulasitiki okubushelelezi uma kuqhathaniswa namathuluzi e-aluminium alloy.Ngakho-ke cabangela isikhunta sensimbi uma izingcezu zinomsebenzi wobuhle odinga izinga eliphansi lokumahhadla kwendawo.

Izinto zokubumba

Uhlu olubanzi lwamapulasitiki okubumba umjovo luyatholakala ukumboza zonke izinhlobo zezingxenye nemisebenzi.Kodwa-ke, akuwona wonke amapulasitiki angakwazi ukufeza ukuphela okufanayo kokubumba komjovo.Amanye ama-polymer afaneleka kangcono ukuqedwa okubushelelezi, kanti amanye afaneleka kangcono ukuqina ukuze athole indawo ebhalwe kakhudlwana.

Izimfanelo zamakhemikhali nezomzimba ziyahluka phakathi kwezinto zokubumba umjovo.Izinga lokushisa elincibilikayo, isibonelo, liyisici esibalulekile emandleni wempahla ukunikeza ikhwalithi ethile yendawo.Izithasiselo nazo zinomthelela emphumeleni womkhiqizo oqediwe.Ngenxa yalokho, kubalulekile ukuhlola izinto ezihlukahlukene ngaphambi kokunquma ukuthungwa kwendawo.

Ngaphezu kwalokho, izithasiselo ezibonakalayo ezifana nesigcwalisi nama-pigments zingase zibe nomthelela ekuqedeni okungaphezulu kwento ebunjiwe.Amathebula asesigabeni esilandelayo abonisa ukusebenza kwezinto ezimbalwa zokubumba umjovo zokuqokwa kokuphela kwe-SPI.

Ukufaneleka kokubalulekile kokuqedwa kwangaphezulu kweBanga le-SPI-A

| Okubalulekile | A-1 | A-2 | A-3 |

| I-ABS | Isilinganiso | Isilinganiso | Kuhle |

| I-Polypropylene (PP) | Akunconyiwe | Isilinganiso | Isilinganiso |

| I-Polystyrene (PS) | Isilinganiso | Isilinganiso | Kuhle |

| I-HDPE | Akunconyiwe | Isilinganiso | Isilinganiso |

| Inayiloni | Isilinganiso | Isilinganiso | Kuhle |

| I-Polycarbonate (PC) | Isilinganiso | Kuhle | Kuhle kakhulu |

| I-Polyurethane (TPU) | Akunconyiwe | Akunconyiwe | Akunconyiwe |

| I-Acrylic | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

Ukufaneleka kokubalulekile kokuqedwa kwangaphezulu kweBanga le-SPI-B

| Okubalulekile | B-1 | B-2 | B-3 |

| I-ABS | Kuhle | Kuhle | Kuhle kakhulu |

| I-Polypropylene (PP) | Kuhle | Kuhle | Kuhle kakhulu |

| I-Polystyrene (PS) | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| I-HDPE | Kuhle | Kuhle | Kuhle kakhulu |

| Inayiloni | Kuhle | Kuhle kakhulu | Kuhle kakhulu |

| I-Polycarbonate (PC) | Kuhle | Kuhle | Isilinganiso |

| I-Polyurethane (TPU) | Akunconyiwe | Isilinganiso | Isilinganiso |

| I-Acrylic | Kuhle | Kuhle | Kuhle |

Ukufaneleka kokubalulekile kokuqedwa kwangaphezulu kweBanga le-SPI-C

| Okubalulekile | C-1 | C-2 | C-3 |

| I-ABS | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| I-Polypropylene (PP) | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| I-Polystyrene (PS) | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| I-HDPE | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| Inayiloni | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| I-Polycarbonate (PC) | Isilinganiso | Akunconyiwe | Akunconyiwe |

| I-Polyurethane (TPU) | Kuhle | Kuhle | Kuhle |

| I-Acrylic | Kuhle | Kuhle | Kuhle |

Ukufaneleka kokubalulekile kokuqedwa kwangaphezulu kweBanga le-SPI-D

| Okubalulekile | D-1 | D-2 | D-3 |

| I-ABS | Kuhle kakhulu | Kuhle kakhulu | Kuhle |

| I-Polypropylene (PP) | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| I-Polystyrene (PS) | Kuhle kakhulu | Kuhle kakhulu | Kuhle |

| I-HDPE | Kuhle kakhulu | Kuhle kakhulu | Kuhle kakhulu |

| Inayiloni | Kuhle kakhulu | Kuhle kakhulu | Kuhle |

| I-Polycarbonate (PC) | Kuhle kakhulu | Akunconyiwe | Akunconyiwe |

| I-Polyurethane (TPU) | Kuhle kakhulu | Kuhle kakhulu | Kuhle |

| I-Acrylic | Isilinganiso | Isilinganiso | Isilinganiso |

Amapharamitha wokubumba

Ijubane lomjovo nezinga lokushisa lithinta ukuphela kwendawo ngezizathu ezimbalwa.Uma uhlanganisa isivinini somjovo osheshayo nezinga lokushisa eliphakeme lokuncibilika noma isikhunta, umphumela uzothuthukiswa ukucwebezela noma ukushelela kwendawo yengxenye.Eqinisweni, isivinini somjovo osheshayo sithuthukisa ukucwebezela okuphelele nokushelela.Ukwengeza, ukugcwaliswa okusheshayo kwesigxobo sesikhunta kungakhiqiza imigqa ye-weld engabonakali kanye nekhwalithi eqinile yobuhle engxenyeni yakho.

Ukunquma indawo engaphezulu kwengxenye kuwukucatshangelwa okubalulekile ekuthuthukisweni komkhiqizo wonke futhi kufanele kucatshangelwe ngesikhathi senqubo yokuklama ukuze kuzuzwe imiphumela oyifunayo.Uke wakucabangela ukuphela kokusetshenziswa kwengxenye ebunjiwe yomjovo wakho?

Vumela u-Xiamen Ruicheng akusize unqume endaweni engaphezulu ethuthukisa ubuhle nokusebenza kwengxenye yakho.

Isikhathi sokuthumela: May-22-2023