Ukubumba irabha kuyinqubo yokukhiqiza ebandakanya ukubumba izinto zenjoloba zibe amafomu nobukhulu obuthile.Le nqubo ivame ukusetshenziselwa ukukhiqiza imikhiqizo ehlukahlukene yenjoloba, kuhlanganise nezimpawu, ama-gaskets, ama-O-rings, kanye nezingxenye ezihlukahlukene zezimboni.

Kunezindlela ezimbalwa zokubumba irabha, okuhlanganisa ukubumba kokucindezelwa, ukubumba ukudlulisa, ukubumba umjovo, nokubumba umjovo we-liquid.Indlela ngayinye inezinzuzo zayo futhi ifanele izinhlobo ezahlukene zemikhiqizo yenjoloba.

Ukubumba irabha kuyinqubo eguquguqukayo evumela ukukhiqizwa kobunjwa obuyinkimbinkimbi kanye nemiklamo eyinkimbinkimbi.Isetshenziswa kakhulu ezimbonini ezifana nezezimoto, i-aerospace, electronics, kanye nemishini yezokwelapha.

Sekukonke, ukubumba kwerabha kudlala indima ebalulekile ekwenziweni kwemikhiqizo yenjoloba eyahlukene, kuhlinzeka ngendlela engabizi nephumelelayo yokukhiqiza izingxenye zekhwalithi ephezulu.

Namuhla sizonaka ukukubonisa mayelana nobuchwepheshe bokubumba irabha kusuka kuhlobo lobuchwepheshe, izinzuzo zokubumba irabha kanye nezicelo.

KUYINI UKUBUNDA IRHABU?

Ukubumba irabha kuyinqubo yokukhiqiza esetshenziselwa ukuguqula irabha engelapheki ibe umkhiqizo osebenzisekayo.Lokhu kufezwa ngezinqubo ezihlukahlukene, okuhlanganisa ukushisa nokulungisa kabusha irabha emgodini wensimbi.Izinhlobo ezintathu eziyinhloko zokubumba ukubumba umjovo, ukubunjwa kokucindezela, nokubunjwa kokudlulisa.

Izinhlobo ezintathu zobuchwepheshe bokubumba irabha

Ukubumba umjovo wenjoloba kufezwa ngokujova irabha engakapholi esibunjeni.Irabha ihlala ekubunjweni isikhathi esithile kuze kube yilapho ivuvukala ibe sesimweni sayo sokugcina.Nakuba ukubumba umjovo kuwuhlobo lokubumba irabha, kungasetshenziswa ezintweni eziningi ezahlukene, njengensimbi nengilazi.

I-Rubber Compression Molding

Ukubunjwa kwenjoloba yokucindezelwa kwenziwa ngokubeka umumo owenziwe ngaphambili werabha engapholikile emgodini wesikhunta esishisayo bese usebenzisa umfutho we-hydraulic ukuze uyivale.Irabha igcinwa endaweni eshisayo kuze kube yilapho ibunjwa ngendlela yayo yokugcina.

I-Rubber Transfer Molding

Ukubunjwa kokudlulisa irabha kufezwa ngokulayisha inani elithile lenjoloba engelashiwe ethangini lokudlulisa.I-punch iyavalwa bese i-preform iphushwa engxenyeni yengxenye ngokusebenzisa umgijimi kanye nesistimu yesango.Injoloba ibanjelwe endaweni eshisayo isikhathi esithile ukuze iyelapha ukuze ibe sesimweni sayo sokugcina.

Umlingo Wokubumba Irabha

Ukubumba irabha kuyinqubo eguquguqukayo nephumelelayo ekuvumela ukuthi uphindaphinde kalula imininingwane eyinkimbinkimbi futhi udale izimo eziyinkimbinkimbi.Kungakhathaliseki ukuthi ungumklami womkhiqizo, iciko, noma unjiniyela, ukuqonda izici ezihlukahlukene zokubumba iraba kunganikeza amaphrojekthi akho amandla amakhulu.

Ikhophi enembile

Esinye sezici ezivelele zokubumba irabha amandla ayo okukhiqiza imininingwane emincane kakhulu.Lolu hlobo lokukhiqiza kabusha lubaluleke kakhulu ezimbonini lapho imiklamo eyinkimbinkimbi ibalulekile.Izibonelo zifaka phakathi ukwenziwa kobucwebe, ukwenziwa kwesithombe esincane, noma ukwelapha amazinyo okubuyisela.

Ukuguquguquka kwezinto

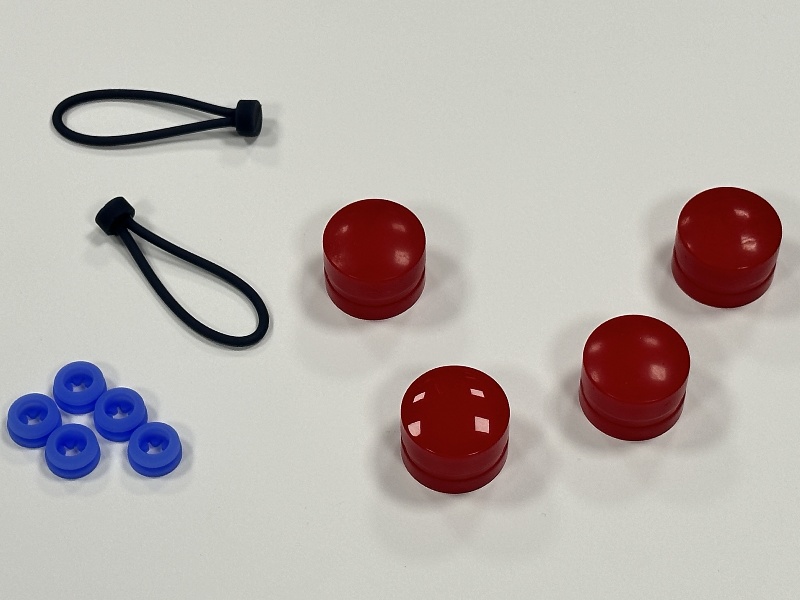

Isikhunta senjoloba singenziwa ngezinto ezihlukahlukene, kuhlanganise ne-resin, ipulasitiki, ngishoizinto ezisezingeni lokudlanjengezigqoko zokuvala.Lokhu kuguquguquka kuvula umhlaba wamathuba okuhlola kanye nokusungula izinto emikhakheni eyahlukene.

Ukusebenza kahle kwezindleko

Ubuchwepheshe bokubumba irabha obuthuthukile buhlinzeka ngezixazululo ezibiza izindleko zokukhiqiza okuncane nokukhulu.Ikhono lokwenza isikhunta esinembile kunciphisa ukuchithwa kwezinto ezibonakalayo, konga imali ngokuhamba kwesikhathi.

Yonga isikhathi

Isivinini sezinqubo zokubumba irabha, njengokubumba umjovo, kunganciphisa kakhulu izikhathi zokukhiqiza.Lokhu kusho ukuthi amaphrojekthi akho aphenduka ngokushesha futhi ungahlangabezana nezinsuku zokugcina eziqinile.

Inkululeko yokuklama

Ubuchwepheshe bokubumba irabha bukunikeza inkululeko yokuhlola imiklamo eyinkimbinkimbi okungenzeka kube nzima ukuyifinyelela ngezinye izindlela.Lokhu kuvumelana nezimo kokudala kukuvumela ukuthi ucindezele imingcele yamaphrojekthi akho.

Ukubumba irabha kuyinqubo eguquguqukayo ethola ukusetshenziswa ezimbonini ezihlukahlukene.Ezinye izinhlelo zokusebenza ezijwayelekile zokubumba irabha zihlanganisa:

1. Imboni yezimoto: Ukubumba irabha kusetshenziselwa ukukhiqiza izinhlobonhlobo zezingxenye zezimoto ezifana nezimpawu, ama-gaskets, ama-O-rings, ama-hoses, nama-dampeners okudlidliza.

2. Imboni yezokwelapha: Ukubumba irabha kusetshenziselwa ukukhiqiza izinto zezokwelapha, njengezigxivizo, ama-gaskets, kanye nezingxenye zenjoloba ezenziwe ngokwezifiso zemishini yezokwelapha.

3. Imboni yezogesi: Ukubumba irabha kusetshenziselwa ukukhiqiza izembozo zokuzivikela, ama-grommets, kanye nezimpawu zezinto zikagesi kanye nezingxenye.

4. Imboni yezimpahla zabathengi: Ukubumba kwerabha kusetshenziselwa ukukhiqiza imikhiqizo ehlukahlukene yabathengi, okuhlanganisa izinto zokubambelela zenjoloba, ama-seal, nama-gaskets ezinto zikagesi zasendlini namathuluzi.

5. Imboni yezimpahla zemidlalo: Ukubumba irabha kusetshenziselwa ukukhiqiza izingxenye zezimpahla zemidlalo, njengezibambo, izigxivizo, nezinsimbi zokuzivikela.

6. Amathoyizi: Izibalo zesenzo, ukubumba kwerabha kwenza ukukhiqizwa kwezibalo nezinhlamvu zenjoloba eziguquguqukayo neziqinile.

Lezi izibonelo ezimbalwa nje zezicelo eziningi zokubumba irabha kuzo zonke izimboni ezahlukene.Inqubo ihlonishwa ngekhono layo lokukhiqiza izingxenye zenjoloba eziklanywe ngokwezifiso ngokunemba okuphezulu nokuqina.

Isifinyezo

Lesi sihloko sihlaziya izici zokubumba i-rubber, , kanye nezindlela zokubumba, okuthemba ukuthi kuzosiza iphrojekthi yakho yezinto zenjoloba.

I-athikili ikhuluma ngohlobo lobuchwepheshe lokubumba i-Rubber Molding kanye nezinzuzo zayo, ezidinga ulwazi oluphezulu lwabahlinzeki besikhunta sokujova nabahlinzeki bemikhiqizo yokubumba umjovo.

Uma unephrojekthi ebandakanya lezi zinqubo ezimbili, kuyanconywa ukuthi uqinisekise ukuthi imboni yokubumba umjovo kanye nefekthri yomkhiqizo wokubumba umjovo inolwazi ekwenzeni imikhiqizo efanayo ukuze kuqinisekiswe ukuqaliswa kahle kwephrojekthi noma ungakwazi.Xhumana nathi, amaqembu ethu ochwepheshe azophendula imibuzo yakho.

Isikhathi sokuthumela: May-13-2024