1.Ukwelashwa Kokumboza: Enye yezindlela ezijwayelekile zokwelashwa kwendawo yehadiwe wukwelashwa kokumboza, okufana nokufaka i-galvanizing, i-nickel plating, kanye ne-chroming.Izembatho zinikeza ungqimba oluvikelayo endaweni yensimbi, okwandisa ukumelana nokugqwala kwawo futhi kuthuthukise ukubukeka.Izembatho nazo zingandisa ubulukhuni nokumelana nokugqoka kwensimbi.

I-2.Ukwelashwa Kokupenda: Ukudweba kuyindlela evamile yokwelashwa kwendawo yehadiwe, lapho kusetshenziswa khona ukunamathela okuvikelayo ngokufafaza upende noma ukumboza endaweni yensimbi.Ukudweba kunganikeza imibala ehlukahlukene kanye nemiphumela, ukuthuthukisa ukubukeka nokuhlinzeka ngemisebenzi efana nokumelana nokugqwala nokumelana nokuklwebheka.

3.Ukwelashwa Kokushisa: Ukwelashwa kokushisa kuhilela ukushintsha isakhiwo kanye nezakhiwo zezinto ze-hardware ngokufudumeza nokulawula inqubo yokupholisa.Izindlela ezijwayelekile zokwelapha ukushisa zifaka ukucwiliswa, ukucisha, nokuthulisa.Ukwelashwa kokushisa kungathuthukisa ubulukhuni, amandla, nokumelana nokugqwala kwehadiwe ukuze kuhlangatshezwane nezidingo ezithile zohlelo lokusebenza.

4.Ukwelashwa Kokupholisha: Ukupholisha kuyinqubo yokwenza indawo yensimbi ishelele futhi icwebezele ngokusebenzisa izindlela zemishini noma zamakhemikhali.Ukupholisha kungasusa amaphutha, ama-oxide, nokungcola endaweni yehadiwe, kuthuthukise ukubukeka nekhwalithi ethintekayo.

5.Ukuxubha:Ukuxubha kuyindlela evamile yokuqeda insimbi esetshenziswa ngokuyinhloko ukushintsha ukubukeka nokuthungwa kwezinsimbi.Isetshenziswa ezinhlobonhlobo zezinsimbi ezifana nensimbi engagqwali, i-aluminium nethusi.Ukuxubha kunikeza ukubukeka nokuzwakala okuhlukile ensimbi ngokuphatha ngokumshini noma ngokwekhemikhali ingaphezulu lensimbi ukuze kukhiqizwe ukuthungwa komugqa noma imihuzuko.

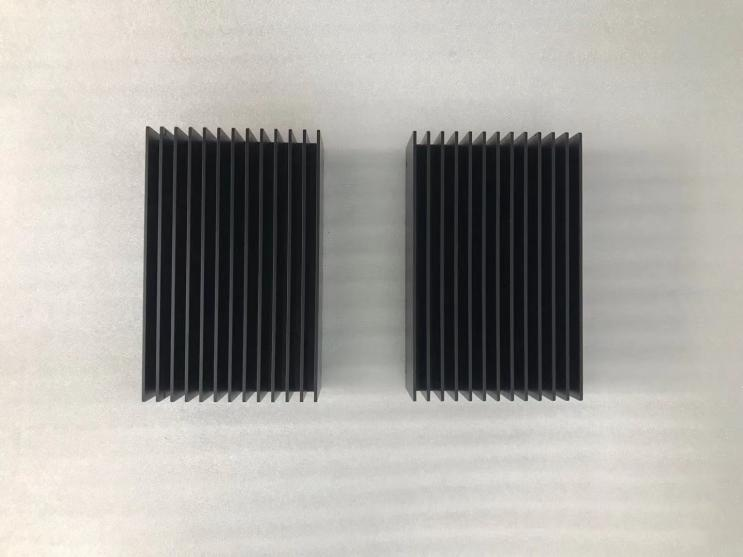

6.I-Anodizing:I-Anodizing iyindlela evamile yokwelapha engaphezulu esetshenziselwa i-aluminium nama-alloys ayo.Kubandakanya ukwakheka kongqimba lwe-oxide ebusweni be-aluminium ngenqubo ye-electrochemical, okuthuthukisa ukumelana nokugqwala kwayo, ukuqina, kanye nokungagugi.

7.Ukudweba nge-laser:Ukudweba nge-laser kuyinqubo esebenzisa ubuchwepheshe be-laser ukuze kuqoshwe indawo engaphezulu yento.Ihwamulisa noma ikhiphe i-oxidize into engaphezulu kwento ngokugxilisa kanye nemisebe ye-laser enamandla amakhulu, okuholela kuphethini, umbhalo noma isithombe ekujuleni noma ukukhululeka okungajulile.

8.Ukuba mnyama: Ukwenza mnyama wukwelapha okungaphezulu okuvame ukusetshenziselwa imikhiqizo yensimbi, ikakhulukazi izinto zensimbi.Isetshenziselwa ukwenza mnyama umbala futhi ikhulise ukumelana nokugqwala komhlaba ngokwenza ungqimba lwe-oxide emnyama endaweni yensimbi.

I-9.Dacromet (i-Dacro) :I-Dacromet (i-Dacro) igama lokuhweba lensimbi yokuqedela kanye ne-anti-corrosion coating.Kuwubuchwepheshe bokunamathela obuthuthukisiwe obusetshenziswa ngokuyinhloko ukuvikela imikhiqizo yensimbi neyensimbi ekugqwaleni nasekufakweni kwe-oxidation.

Izembatho ze-Dacromet ngokuvamile zihlanganisa izingxenye ezilandelayo:

I-Primer engenayo i-Chromate: Lona ungqimba lokuqala lwe-Dacromet enamathelayo, engaqukethe izinhlanganisela ze-chromium eziyingozi.Umsebenzi oyinhloko we-primer ukuhlinzeka ngokunamathela okuhle kakhulu nokumelana nokugqwala ngenkathi uhlinzeka ngesisekelo esifanayo sejazi eliphezulu.

I-Corrosion-resistant Intermediate Coating: Lena ingxenye eyinhloko ye-Dacromet coating.Isendlalelo esimaphakathi siqukethe izinhlobonhlobo ze-corrosion inhibitor kanye nezimibalabala ezimelana nokugqwala ezinqanda ngempumelelo ukugqwala kanye ne-oxidation yendawo yensimbi.

I-Organic Coating: Lona ungqimba olungaphandle kakhulu lwe-Dacromet coating futhi ngokuvamile i-organic resin coating.Ayihlinzeki nje kuphela ngombala kanye nemiphumela yokuhlobisa, kodwa futhi yandisa ukuqina nokumelana nokuqala kwe-coating.

10.I-Sandblasting: I-Sandblasting, eyaziwa nangokuthi ukuhlanza i-sandblasting, ukupholishwa kwe-sandblasting, noma i-sandblasting yomoya, kuyindlela evamile yokulungisa indawo esetshenziselwa ukuhlanza, ukwenza i-roughen, noma ukuthuthukisa ukuthungwa kwendawo yento.

Lapho ukhetha ukwelashwa kwendawo yensimbi, izici eziningana zidinga ukucatshangelwa:

Inhloso nezimfuneko: Okokuqala, thola inhloso yakho ethile kanye nezidingo zokwelashwa kwendawo yensimbi.Ingabe uhlose ukuvikela insimbi ekugqwaleni nasekufakweni kwe-oxidation, ukuthuthukisa ukuthungwa kobuhle, ukwengeza imiphumela yokuhlobisa, noma ukuthuthukisa ukunamathela kokunamathela?Izindlela zokwelashwa ezihlukene zinikeza imiphumela ehlukene ngokusekelwe ezinjongweni nezimfuneko ezihlukahlukene.

Uhlobo lwezinto ezibonakalayo: Cabangela uhlobo nezici zensimbi.Izinsimbi ezihlukene, njengensimbi, i-aluminium, ithusi, njll., zingase zibe nokuvumelana nezimo ezihlukahlukene ezindleleni zokwelashwa ezingaphezulu.Ezinye izinsimbi zingase zijwayele ukugqwala, kanti ezinye zingadinga izindlela zokwelapha ezikhethekile ukuze kuthuthukiswe ukunamathela.

Izimo zemvelo: Qaphela izimo zemvelo umkhiqizo wensimbi ozochayeka kuzo.Uma insimbi izochayeka endaweni enomswakama, ene-asidi, noma ebolayo, ukukhetha indlela yokwelapha engaphezulu enokumelana nokugqwala okuhle kakhulu kubalulekile.Uma insimbi izosetshenziswa ngaphandle, ukumelana nesimo sezulu kanye nokumelana ne-UV nakho kuyizici okufanele zicatshangelwe.

Isabelomali nezindleko: Izindlela ezihlukene zokwelapha ezingaphezulu zingase zibe nezindleko ezihlukene kanye nobunzima bokusebenzisa.Cabangela ibhajethi yakho nezinsiza ezitholakalayo ukuze ukhethe indlela ehambisana namandla akho ezezimali.

Ukuba nokwenzeka nokusebenza: Cabangela ukuba nokwenzeka nokusebenza kwendlela yokwelapha engaphezulu ekhethiwe.Ezinye izindlela zingase zidinge amathuluzi namakhono akhethekile, kanti ezinye zingase zibe lula futhi zifinyeleleke kalula.Qinisekisa ukuthi unempahla edingekayo, amakhono, nezinsiza, noma ungathola usizo lochwepheshe.

Uma ucabangela lezi zici ezingenhla, ungakhetha kusuka ezinhlobonhlobo zezindlela zokwelapha ezifanelekile zensimbi, kufaka phakathi i-sandblasting, i-electroplating, i-hot-dip galvanizing, i-anodizing, i-powder coating, njalonjalo.Uma ungaqiniseki ukuthi iyiphi indlela efaneleka kakhulu esimweni sakho, ungasithinta.U-Xiamen Ruicheng wenze zonke izinhlobo zokwelashwa kwensimbi kozakwethu abaningi futhi uthole ukubuyekezwa okuhle kakhulu.Ubuchwepheshe bethu nolwazi lungakunikeza izeluleko ezinemininingwane esekelwe ezidingweni zakho ezithile.

Isikhathi sokuthumela: Feb-23-2024