Ukuhlaziywa Kwekesi Lomshini We-CNC Le-Aluminium Battery Shell

Imininingwane Yomkhiqizo

Isicelo seklayenti

1. Khiqiza ingxenye njengefayela le-3D ngalinye futhi ulawule ukunemba ngaphakathi kwe-0.05M.

2. Ukuhlolwa kwe-CMM kubhekisela ekubekezeleni komdwebo we-2D.

3. Qiniseka ukuthi umhlangano ulungile.

Ukuhlaziya Kwethu

Ngemva kokuthola imidwebo nezicelo zeKlayenti, onjiniyela bethu abangochwepheshe banokuhlaziya okuphelele nokuqinisekisa ukuthi singakhiqiza le ngxenye ngokuqinile futhi silawule zonke izilinganiso ekubekezeleni.Ukuze siqinisekise ukuthi umhlangano Ulungile, sicele iklayenti ukuthi linikeze umdwebo Womhlangano ukuze uhlole ukuthi akukho ukuphazamiseka kwezinye izingxenye.

Qala ukusebenza

1. Ukuhlela

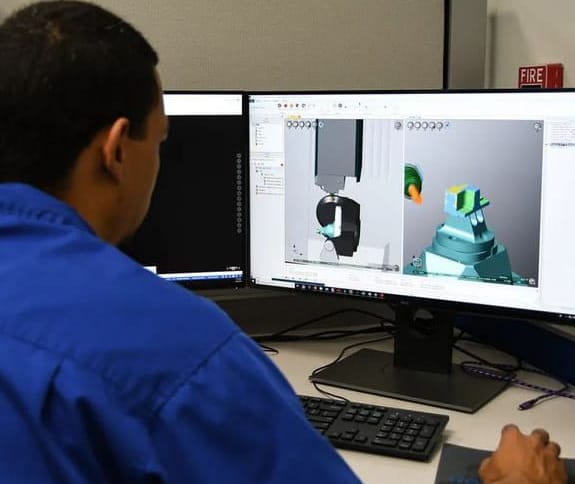

Umhleli wethu we-CNC usebenza ekusetheni izindlela zokusebenza zomshini.

2. CNC machining

Umkhiqizo wenziwa ngomshini ngokuhlelekile nangokushelela njengokulandela izindlela zohlelo esizimisayo.

3. Isandla Esipholishiwe

Indawo engokwemvelo yemikhiqizo ngemva kwe-CNC ilukhuni futhi inezinsimbi nemibese eminingi, Isisebenzi sethu manje sisebenzisa i-sandpaper ukuze sihlanze futhi sipholishe ubuso ukuze sibe nengxenye ebushelelezi ngaphandle kwemiphetho ebukhali.Ingxenye izofakwa esihlabathini kusuka kumaholoholo kuya kuma-sandpaper amahle (400-1500) izinga lokugaya kuze kube yilapho ubuso bubushelelezi.

4.CMM(xhumanisa umshini wokulinganisa) Ukuhlolwa

I-QC yethu ilungisa umshini we-CMM ukuze ube nokuhlolwa okunembile kokunemba kobukhulu, ukunemba kokuma, ukunemba kwejometri kanye nokunemba kwekhonta.

5.Ukuthumela ngemikhumbi

Ngemuva kokuthi i-QC yethu inikeze ukukhanya okuluhlaza kulo mkhiqizo, sizowathumela ngephakheji eliqinile lokuvikela umkhiqizo.Ukuze yonke imikhiqizo izolethwa isesimweni esihle.